Long Life Coconut Liquid Products

Long life coconut liquid products are coconut liquid products sterilized by undergoing strong heat treatment to inactivate microorganisms and heat-resistant enzymes. As such, they can be stored for long periods of time at ambient temperatures without bacterial growth.

Processing long life coconut liquid products

Long life coconut liquid products are coconut liquid products like coconut milk based or coconut water-based beverages, coconut milk or cream sterilized by undergoing strong heat treatment to inactivate microorganisms and heat-resistant enzymes. As such, they can be stored for long periods of time at ambient temperatures without bacterial growth.

Properly processed coconut products are safe and hygienic. Consumers benefit from a product that can be stored for long periods of time without refrigeration. It can also be distributed over long distances and supplied to new markets.

Essentially, there are three heating processes for extending the shelf life of coconut liquid products – pasteurization, sterilization and ultra-high temperature processing. Each process requires specific types of packaging in order to maximize its effect (Table 11.1). The exact shelf life of coconut liquid products depends on the raw materials, processing conditions and type of packaging used.

Microbial load of raw material

Coconuts have a high microbial load, especially those left on the ground after harvesting and transported over long distances. In particular, dehusked mature coconuts contain higher microbial load as the fibres tend to trap soil and dirt. To reduce microbial load, it is recommended that coconut processing includes a cleaning stage during production.

Cleaning efforts vary for young and mature coconuts. For young coconuts, the whole fruit is brushed and washed in potable water to remove soil and dirt. Sanitizing the fruit in a dilute bleach solution further reduces the number of microorganisms on the surface of the young coconut. (FAO,2007)

To reduce microbial load for mature coconuts, they are deshelled and pared down before the white or brown skin kernels are washed. The pieces of coconut kernels are washed with diluted anti-microbial solutions, followed by rinsing with potable water before going into the grinders for coconut milk extraction.

Sterilizing effect on coconut liquid products

When microorganisms and bacterial spores are subjected to heat treatment or any other kind of sterilizing procedure, not all are killed at once. Instead, a certain proportion is destroyed in the given time period, while the remaining portion survives. If the surviving microorganisms are subjected to the same treatment again over the given time period, the same proportion will be destroyed and so on. In other words, a given exposure to sterilizing or disinfectant agents always kills the same proportion of microorganisms present.

Logarithmic death rates of spores

Microorganisms are reduced in a semi-logarithmic fashion when exposed to a lethal effect. As such, the logarithmic function can never reach zero. Sterility, which implies the total absence of all living microorganisms, is therefore impossible.

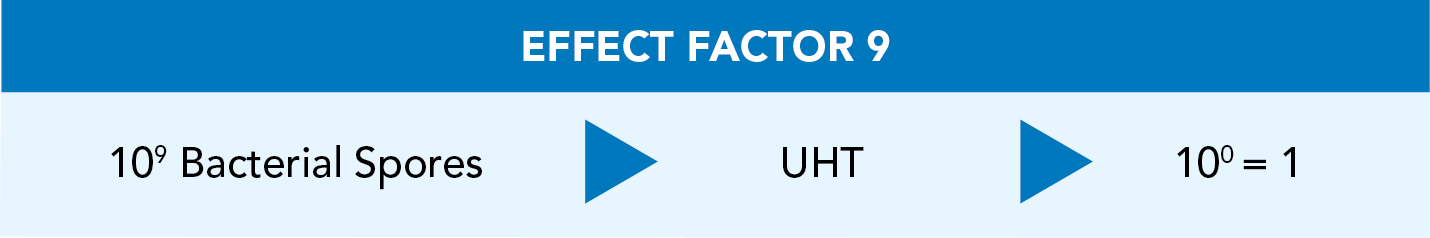

In reality, “sterilizing effect” or “sterilizing efficiency” are more apt descriptions for the number of decimal reductions in counts of bacterial spores achieved by a sterilization process. When a sterilization process is performed every time, it can be characterized by a certain sterilizing effect. An effect factor of 9 here indicates that out of 109 bacterial spores fed into the process, only 1 (100) will survive (Figure 11.1).

Figure 11.1 Sterilizing effect of 9

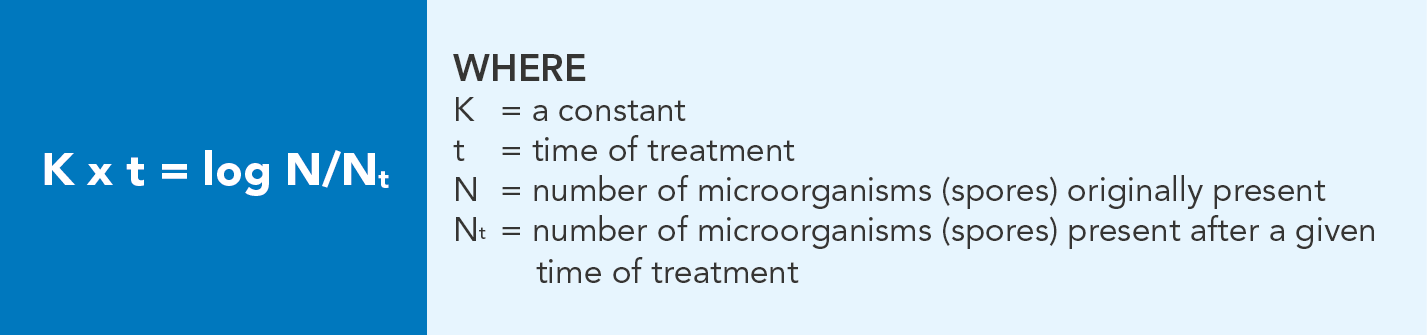

The sterilizing effect is independent of the volume and number of microorganisms (spores). The function is:

Sterilizing effect achieved through UHT

In general, the sterilizing effect depends on the time and temperature combination, as well as the product’s bacteria content.

Bacteria content exists as easy to kill vegetative cells only, or as spore-forming bacteria in a vegetative state. While these bacteria are easily killed in the vegetative state, their spores are difficult to eliminate.

In turn, the heat resistance of the test spores is influenced by the Bacillus strain used, which affects the way spores are produced. Spores of Bacillus subtilis or Bacillus stearothermophilus are generally used as test organisms to determine the sterilizing effect of UHT equipment, especially when strains like B.stearothermophilus form fairly heat-resistant spores. Clostridium botulinum is used to determine the effect of in-container sterilization.

Products to be sterilized usually contain a mixed flora of both vegetative cells and bacterial spores. Unfortunately, high spore counts can be found in products with low total counts, and vice versa. Therefore, the total count determination cannot serve as a reliable base for enumeration of spores in food products. To determine this, Q10 and F0 values serve as a base for the killing of microorganisms.

Q10 value

Ranging from 8-30, Q10 values can be used to determine the killing of bacterial spores. The range widely varies because different bacteria spores react differently to temperature increases.

Q10 values state how many times the speed of a reaction increases if the temperature of the system is raised by 10°C. This is due to the sterilizing effect of a heat process that increases rapidly with rising temperature, which is consistent with the chemical reactions that occur as a consequence of heat treatment.

F0 value

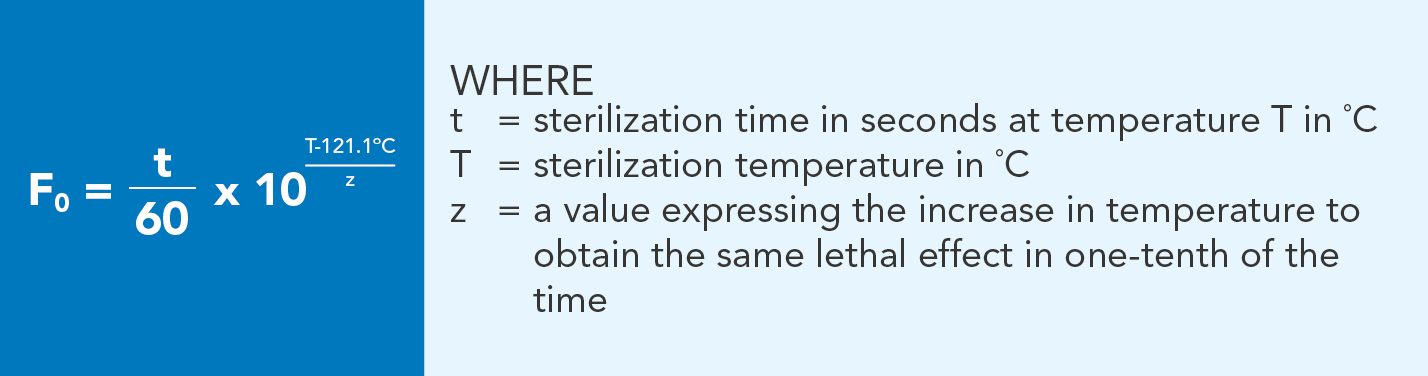

F0 value expresses the relationship between time and temperature of sterilization, where the F-value for a process is the number of minutes required to kill a known population of microorganisms in a given amount of food under specified conditions. The F0 value is based on a z-value of 10°C and states the minutes required at a temperature of 121.1°C to achieve a sterilizing effect of 12D.

The value varies with the origin of the spores (10-10.8°C) and can generally be set as 10°C.

D-value

Decimal reduction time (D-value) is defined as the time required at any given temperature for a 90% reduction (= 1 log value) in viability of microorganism to be affected.

z-value

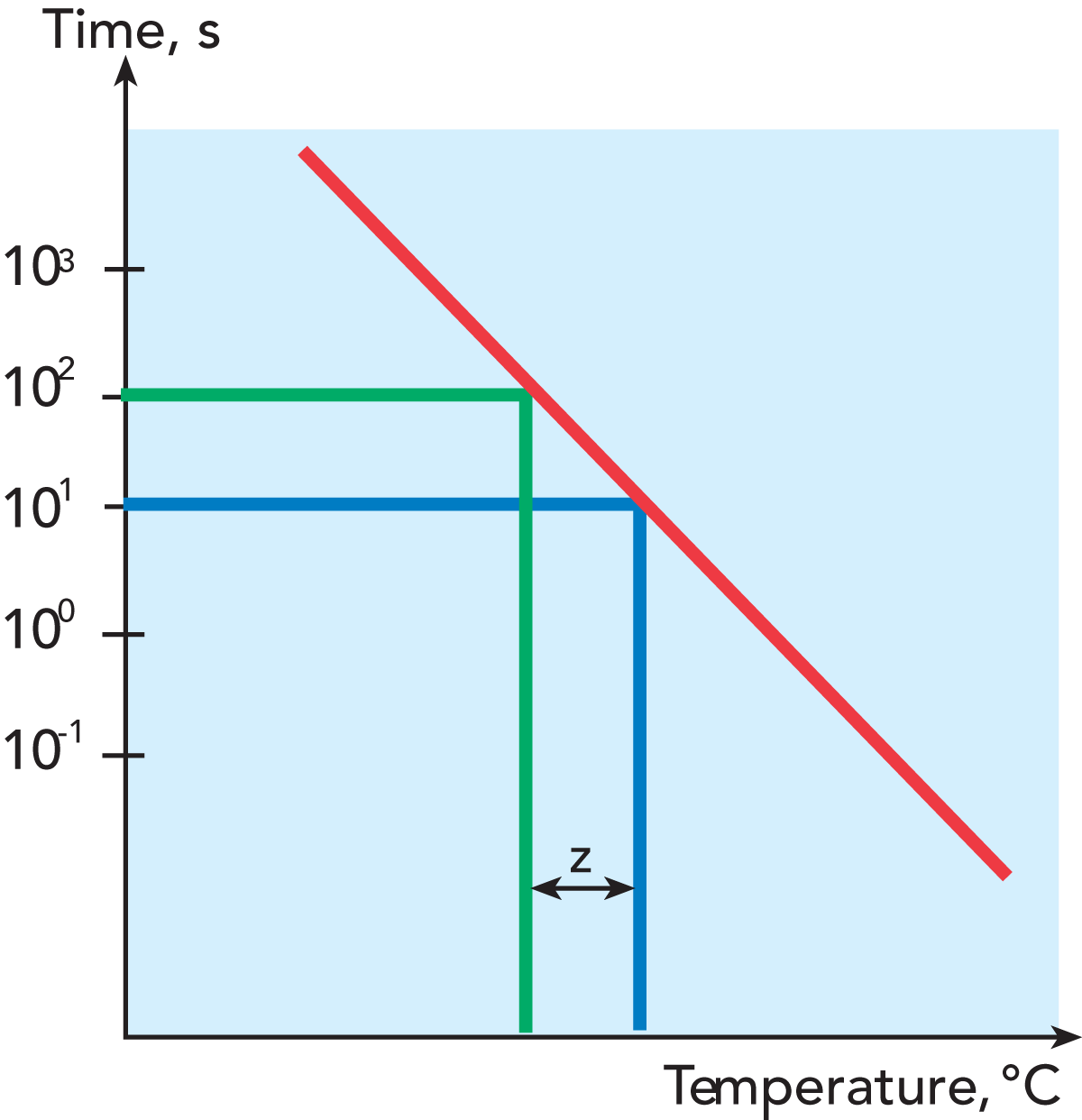

z-value is defined as the temperature increase required to increase the death rate by tenfold. In other words, it is the temperature required to reduce the D value by tenfold (Figure 11.1).

Chemical and bacteriological changes with high heat treatment

During coconut beverage processing, high heat treatment causes multiple chemical and bacteriological changes. It destroys most microorganisms present in the coconut liquid extract and increases the shelf life of the coconut beverage. It is important to remove all microorganisms during heat sterilization. Due to the effectiveness of sterilization, vegetative organisms present in coconut liquid products are more easily killed. On the other hand, resistant spores are more likely to survive as compared to vegetative organisms in some sterilization processes. Resistant spores may survive thermal treatments of temperature and time settings of up to 100°C for 30 minutes.

Although high heat treatment has many benefits, extended heating should be avoided as it leads to the destruction of nutrients, such as essential amino acids and vitamins. It also causes Maillard browning and develops a cooked flavour.

When heat treatment is applied to coconut products, it is important to ensure optimum conditions for sterilizing effectiveness. These include temperature, time, moisture content and pressure to maximize the destruction of microbial spoilage agents, while minimizing the unwanted effects of heat.

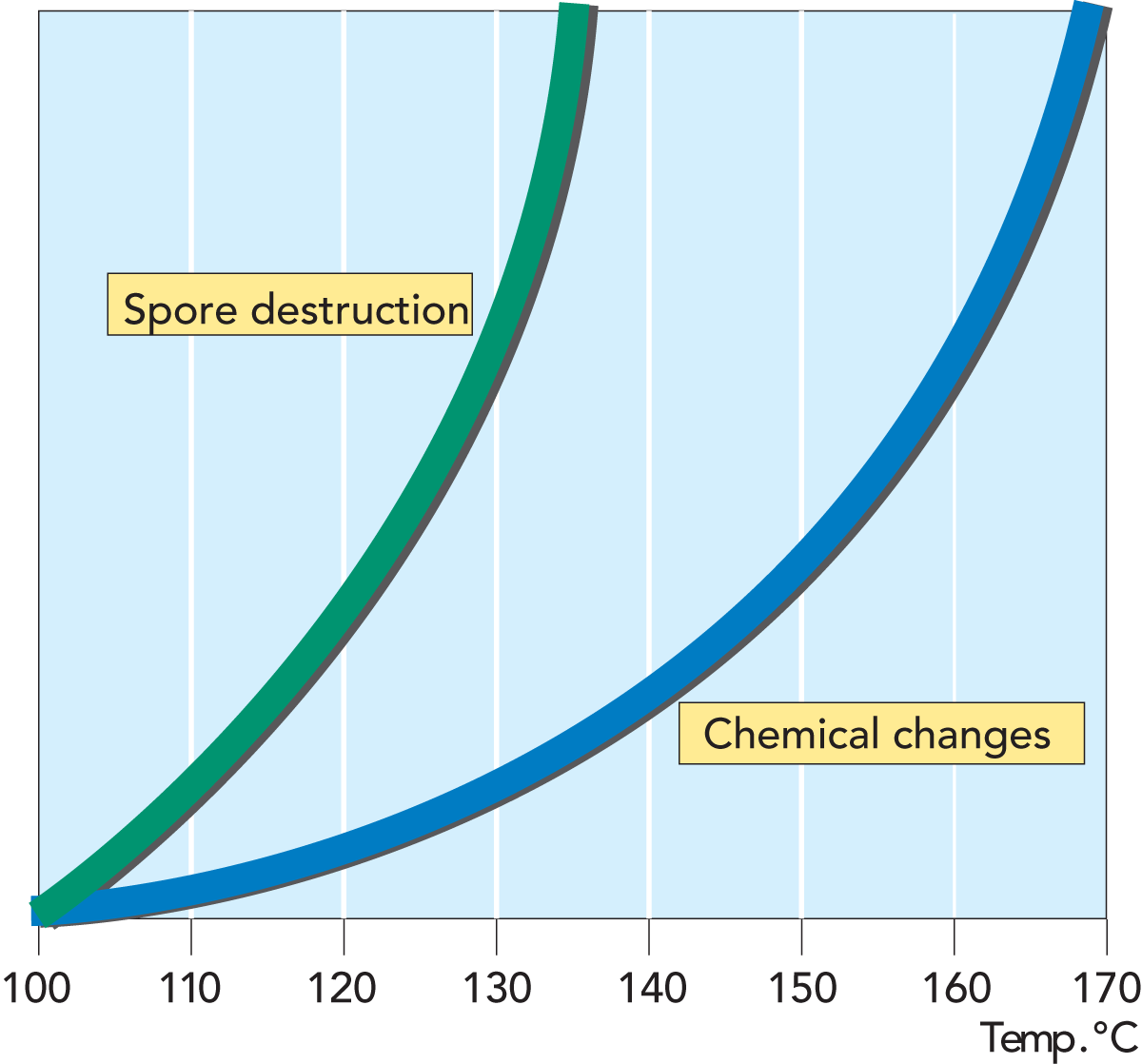

The changes in chemical properties and spore destruction are shown in Figure 11.2. It can be seen that in the range of UHT temperatures, the bacteriological killing effect increases considerably with temperature, whereas the chemical changes remain mild.

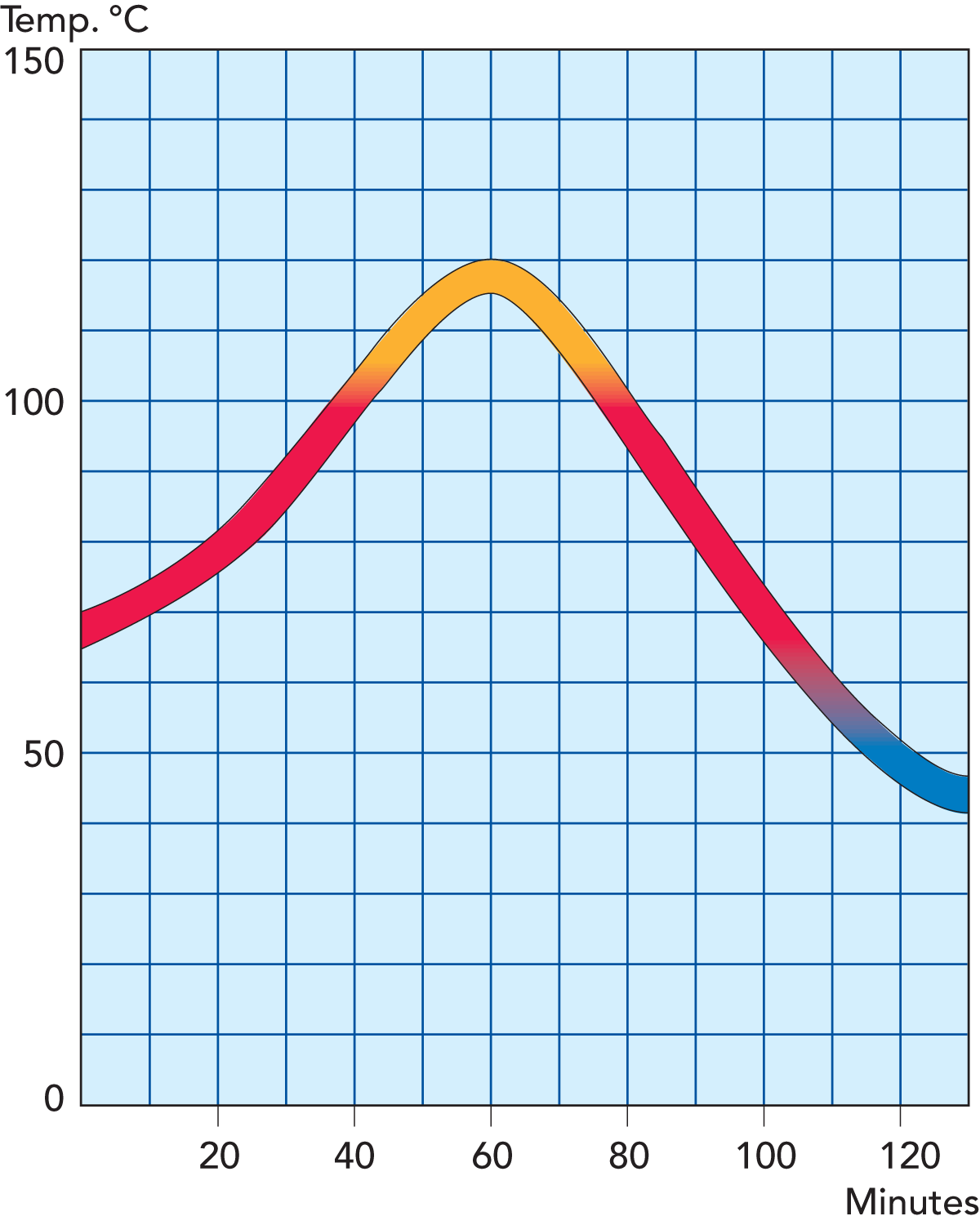

This clearly illustrates the advantages of UHT treatment against in-container sterilization operating at low temperatures for a long time (Figure 11.3). Ultra high temperatures with short holding times (Figure 11.4) can provide a high sterilization effect while causing only minimal chemical changes in the treated product. In-container sterilization operating at low temperatures for a long time leads to more extensive changes in product quality.

Shelf life

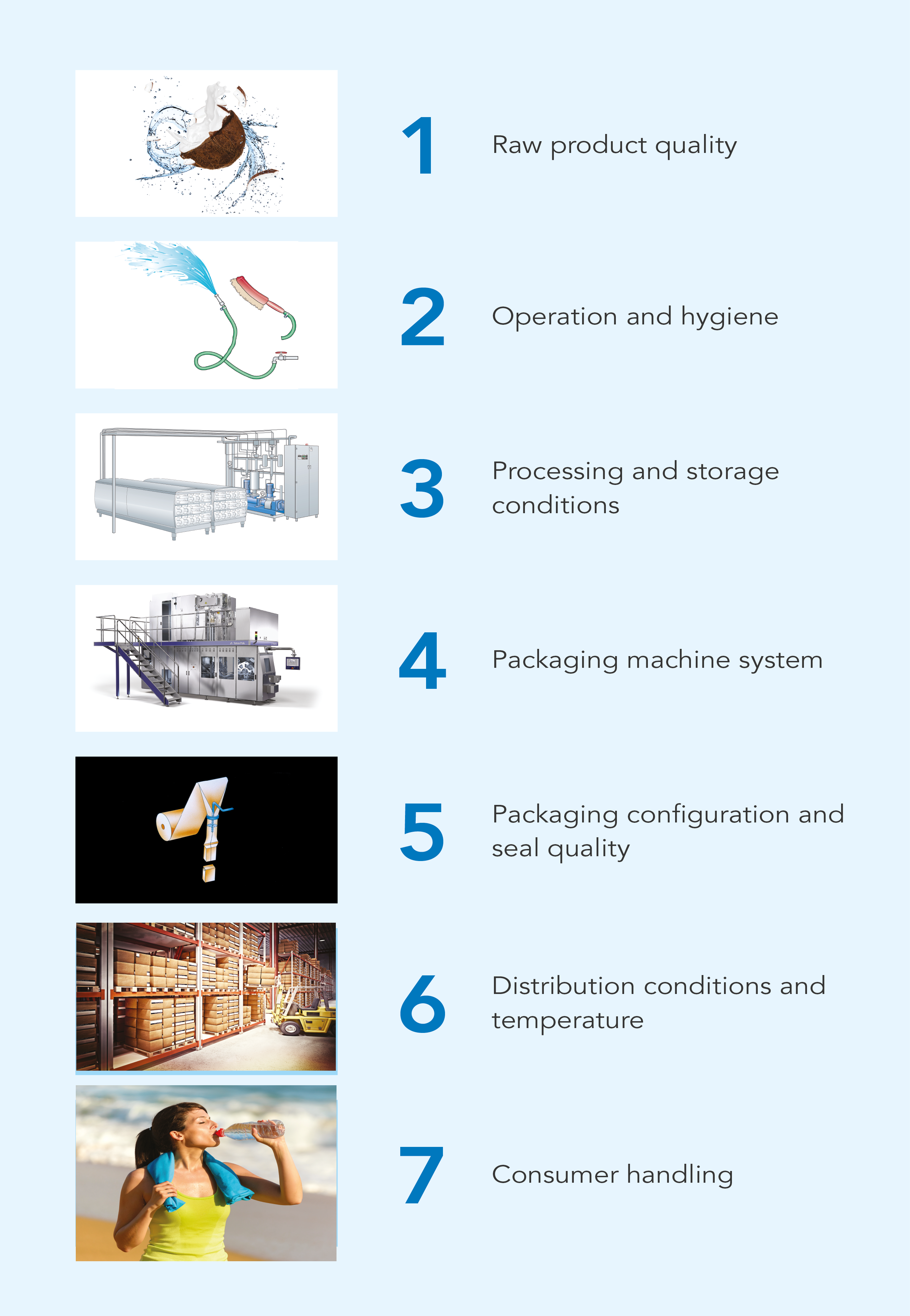

For long life products, shelf life is defined as the time the product can be stored before its quality falls below an acceptable, minimum level. This is determined by the product taste, colour, smell, jellification, sedimentation, fat separation and viscosity.

During storage, the sensory properties of coconut beverages can deteriorate. For coconut water, colour may change from colourless to brown or pink, while turbidity may increase due to flocculation. For coconut milk and its products, separation between oil and aqueous phases may occur, which also affects the viscosity properties. Factors affecting the shelf life of coconut liquid products are shown in Figure 11.5.

Producing long life coconut liquid products

There are two methods used for the production of long life coconut beverages – in-container sterilization and Ultra High Temperature (UHT) treatment.

In-container sterilization

There are two processes used for sterilization in bottles or cans – batch processing in autoclaves and continuous processing, using systems such as vertical hydrostatic towers and horizontal sterilizers.

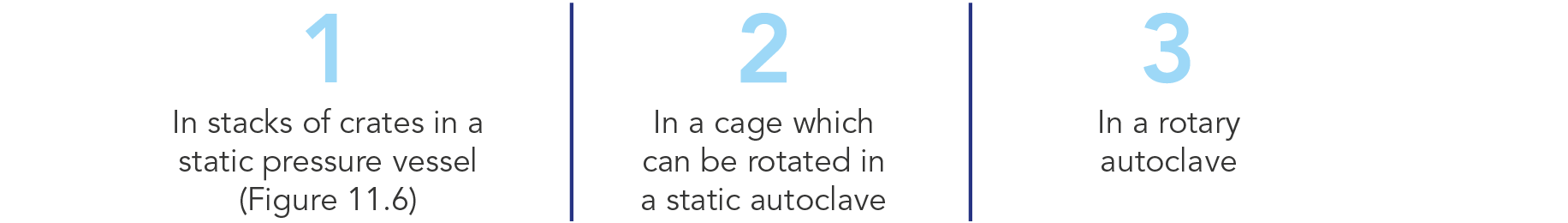

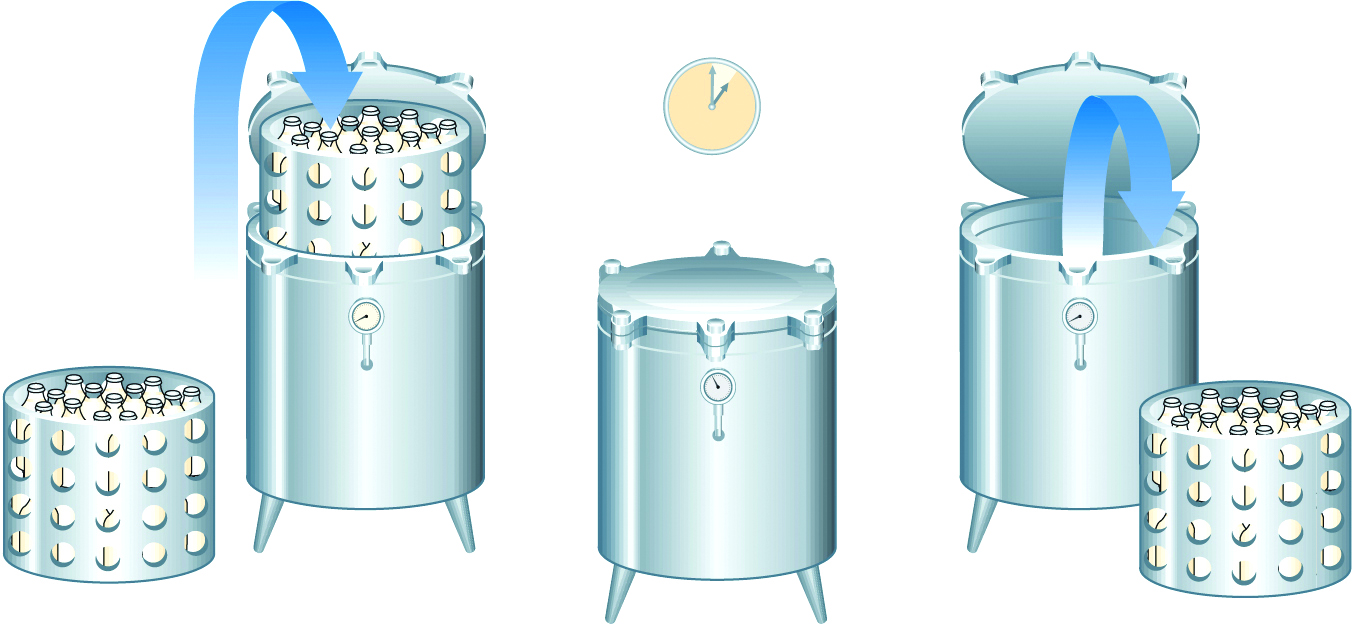

Batch processing

Batch processing can be operated by three methods:

In a rotary autoclave, it has an advantage over the static methods due to a quicker uptake of heat from the heating medium, as well as greater uniformity of treatment for killing bacteria and ensuring colour uniformity. By batch processing in autoclaves, the product is usually preheated, then transferred into clean, heated bottles. As such, heat resistant packaging materials must be used.

The bottles are then capped, placed in a steam chamber and sterilized. Later, the batch is cooled, and the autoclave is filled with a new batch. Since sterilization takes place after bottling or canning, this eliminates the need for aseptic handling. However, heat resistant packaging materials must be used.

Continuous processing

Continuous processing systems are normally preferred when more than ten thousand units per day are produced. For the smooth running of operations, the design of such machines depends on the use of a pressure lock system through which the filled containers pass from low pressure, low temperature conditions into a relatively high pressure, high temperature zone, after which they are subjected to steadily decreasing temperature-pressure conditions, and are eventually cooled with chilled or cold water.

There are two main types of machines available for continuous sterilization, depending on the type of pressure lock system used.

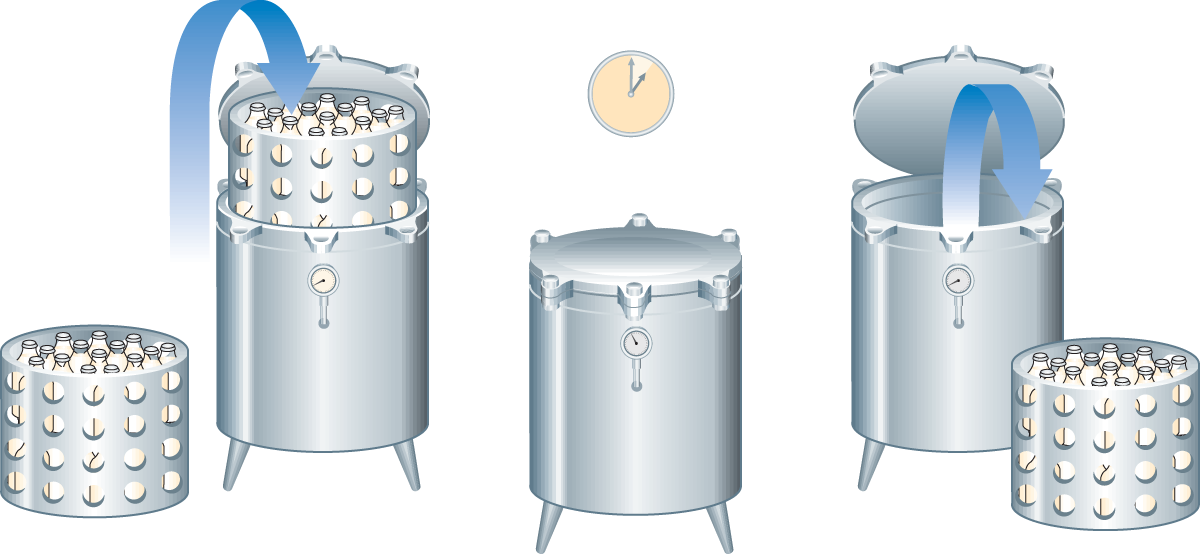

The hydrostatic vertical bottle sterilizer

Often referred to as the tower sterilizer, the hydrostatic vertical bottle sterilizer consists of a central chamber maintained at a sterilizing temperature by steam under pressure, while counterbalanced by the equivalent pressure of water columns.

Water is heated on the inlet side and cooled on the outlet side, while temperatures are adjusted to give maximum heat uptake and abstraction. At the same time, breakage of glass packaging is avoided by thermal shock.

In the hydrostatic tower, the filled containers are slowly conveyed through successive heating and cooling zones. These zones are sized to correspond with the required temperatures and holding times at various treatment stages.

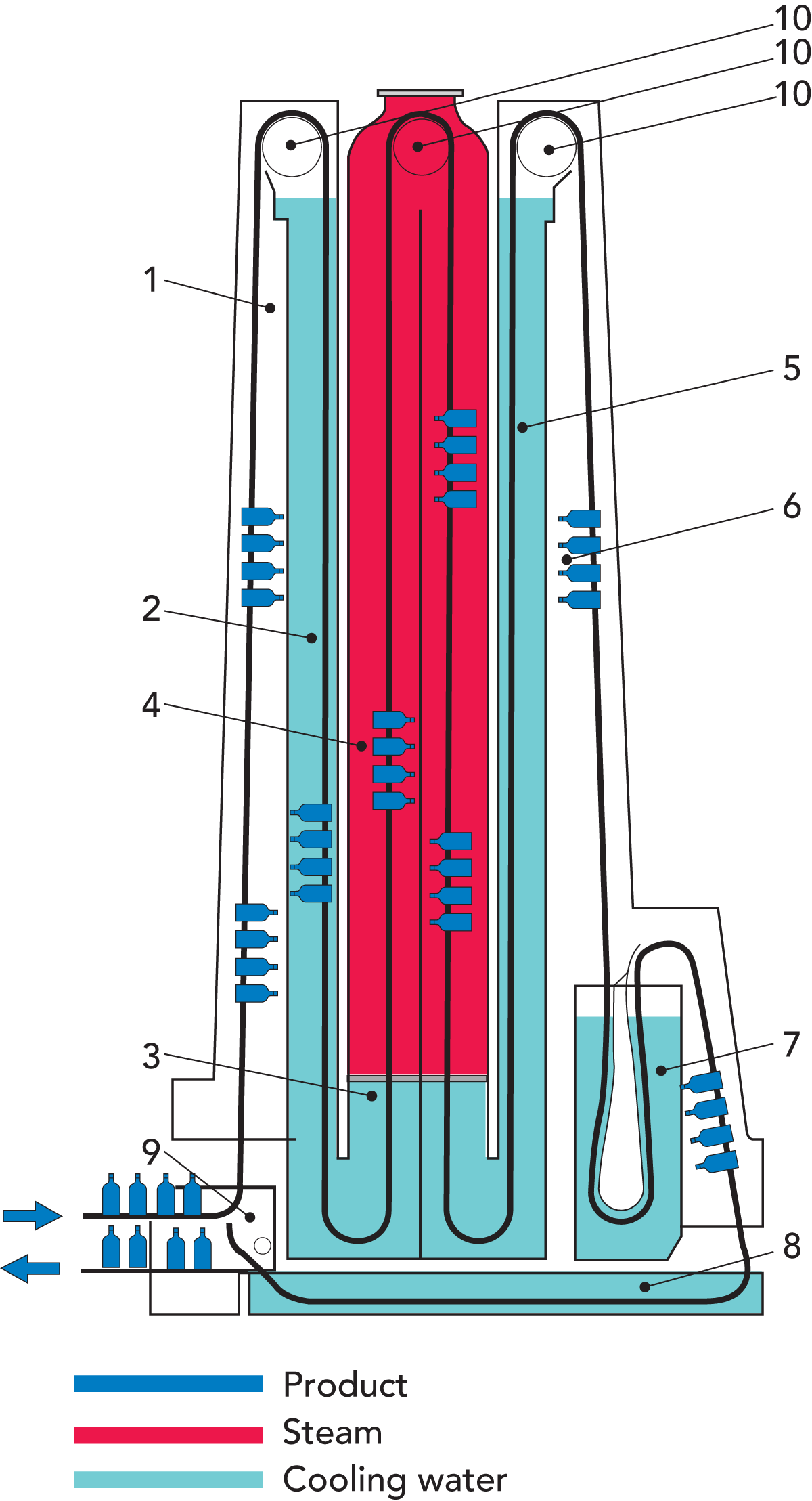

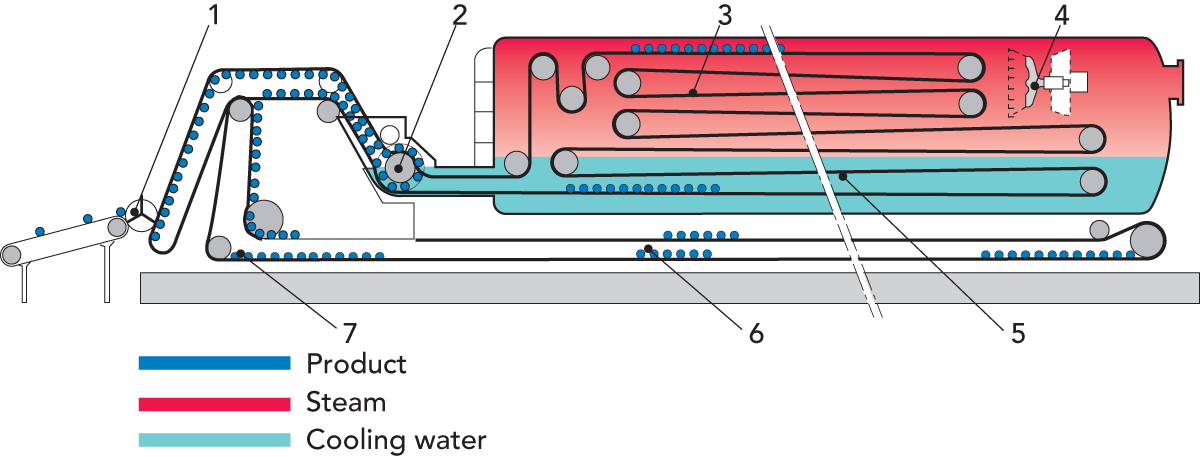

The horizontal rotary valve-sealed sterilizer

The rotary valve sealed sterilizer is a comparatively simple machine with a mechanically driven valve rotor. The filled containers are conveyed into a relatively high pressure, high temperature zone where they are subjected to sterilizing temperatures. The rotary valve sealed sterilizer can be used for the sterilization of plastic and glass bottles, as well as flexible containers of plastic film and laminates.

Ultra high temperature (UHT) treatment

Ultra High Temperature (UHT) is a technique used for preserving liquid food products by exposing them to brief, intensive heating. This treatment destroys the microorganisms in the product with a continuous inflow process. It is based on the rapid heating of the product to the required sterilization temperature, followed by a short period of holding time at that temperature and rapid cooling. The purpose of UHT treatment is to achieve commercial sterility of the product.

UHT treatment conditions vary from product to product, depending on the raw materials used and its microbial load. As such, different coconut liquid products require different UHT treatments.

For example, coconut water is generally more sensitive to heat, as compared to coconut milk. Coconut milk requires higher thermal impact to achieve commercial sterility as it contains fibres and is higher in viscosity (Table 11.2).

In another example, when dairy milk or soya powder is added to coconut water, a higher temperature is recommended. If the microbial load is too high for the UHT treatment to handle, the coconut liquid products can be subjected to an upstream step of pasteurization to lower the microbial load before UHT handles the remaining microorganisms.

Additionally, some countries impose food regulations which have a requirement for UHT treatment of coconut products. For instance, long life coconut liquid products in the USA have to undergo UHT equivalent to F0 of 5 > at 121°C = 5 minutes.

In UHT treatments, the product is first heated before aseptic packaging, which protects the product against light and atmospheric oxygen. This only applies when the product remains under aseptic conditions, so it is necessary to prevent re-infection by packaging the product in previously sterilized packaging materials after heat treatment. Any intermediate storage between treatment and packaging must take place under aseptic conditions. This is why UHT processing is also called aseptic processing.

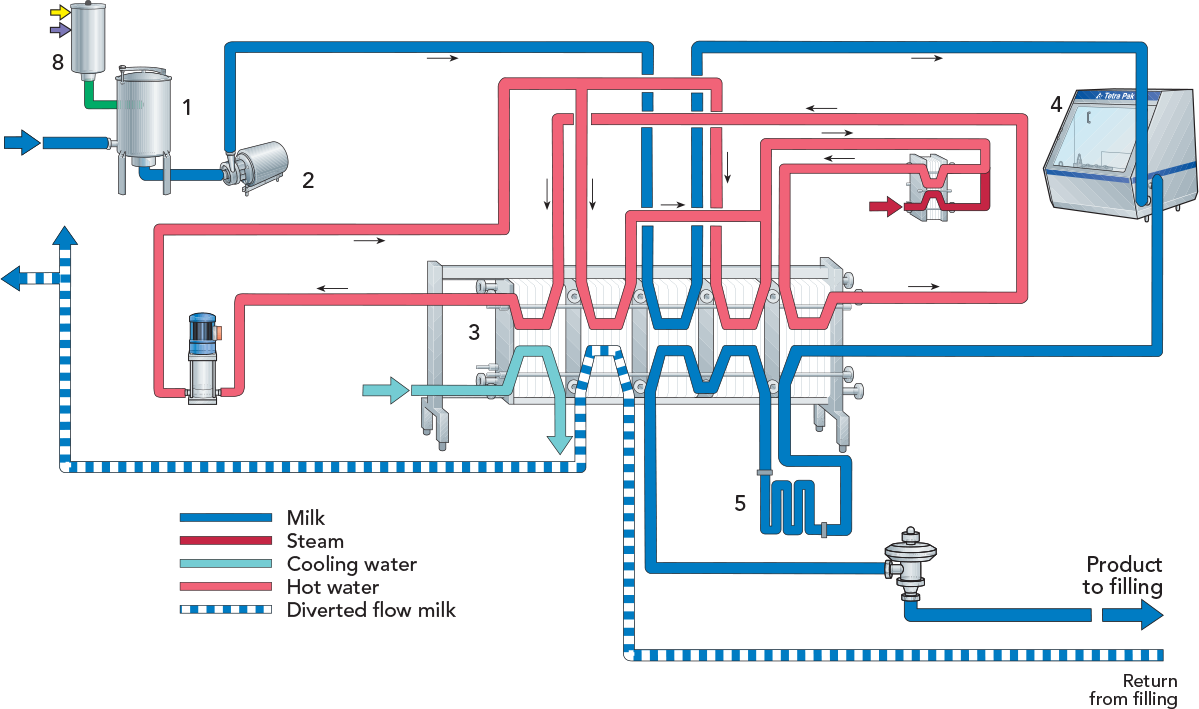

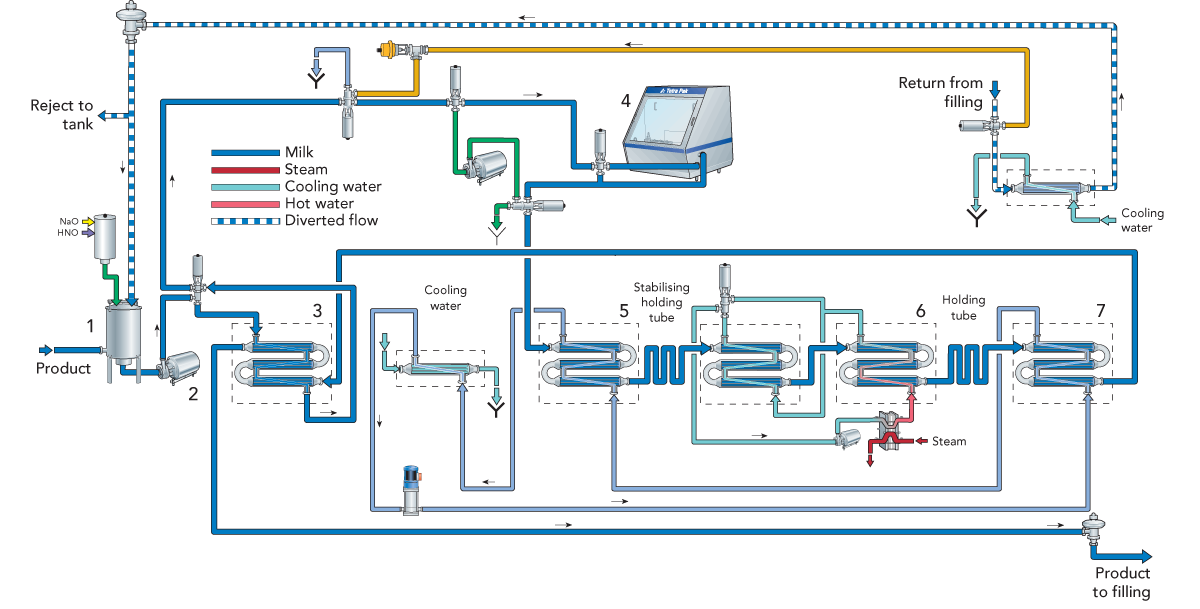

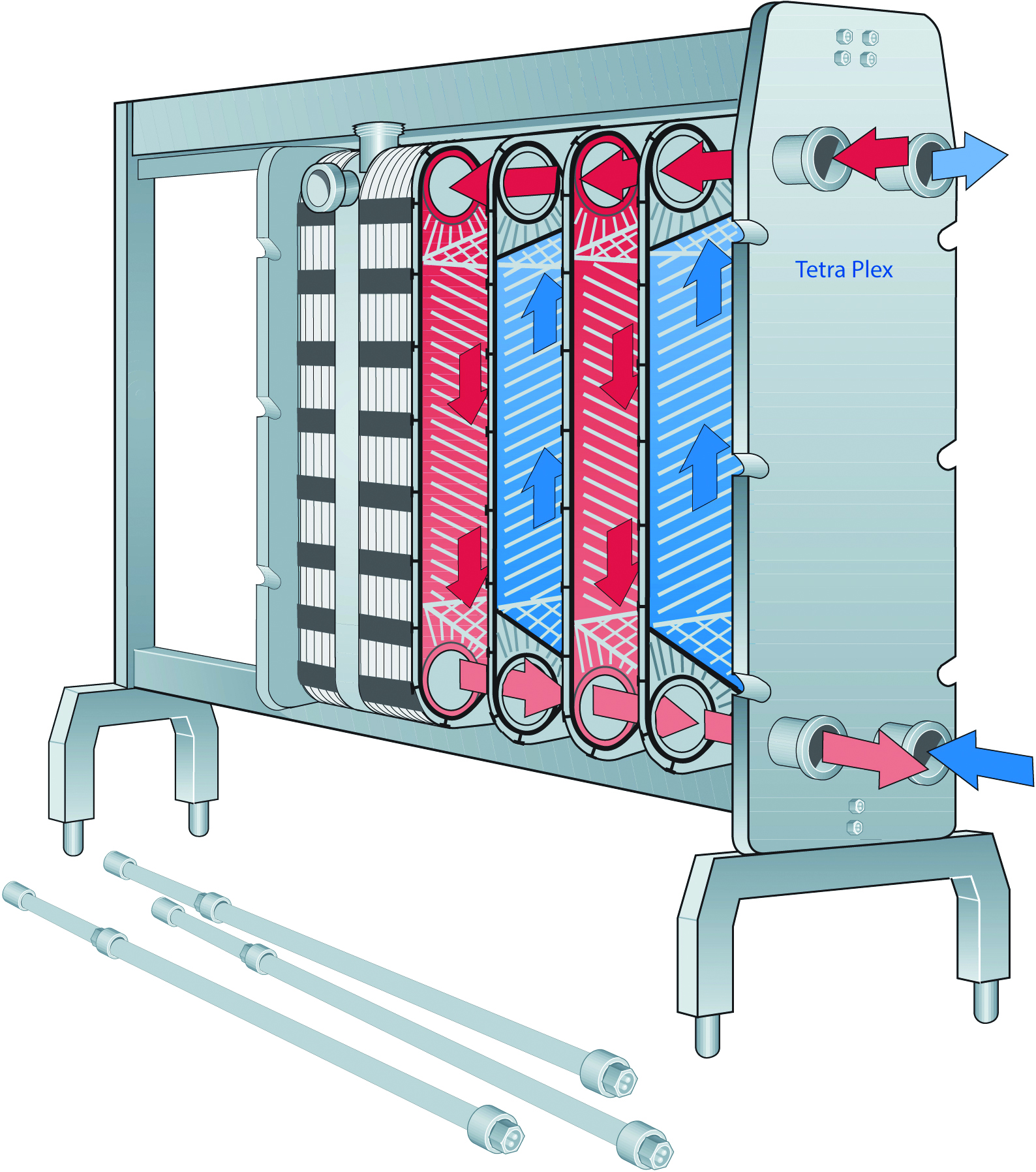

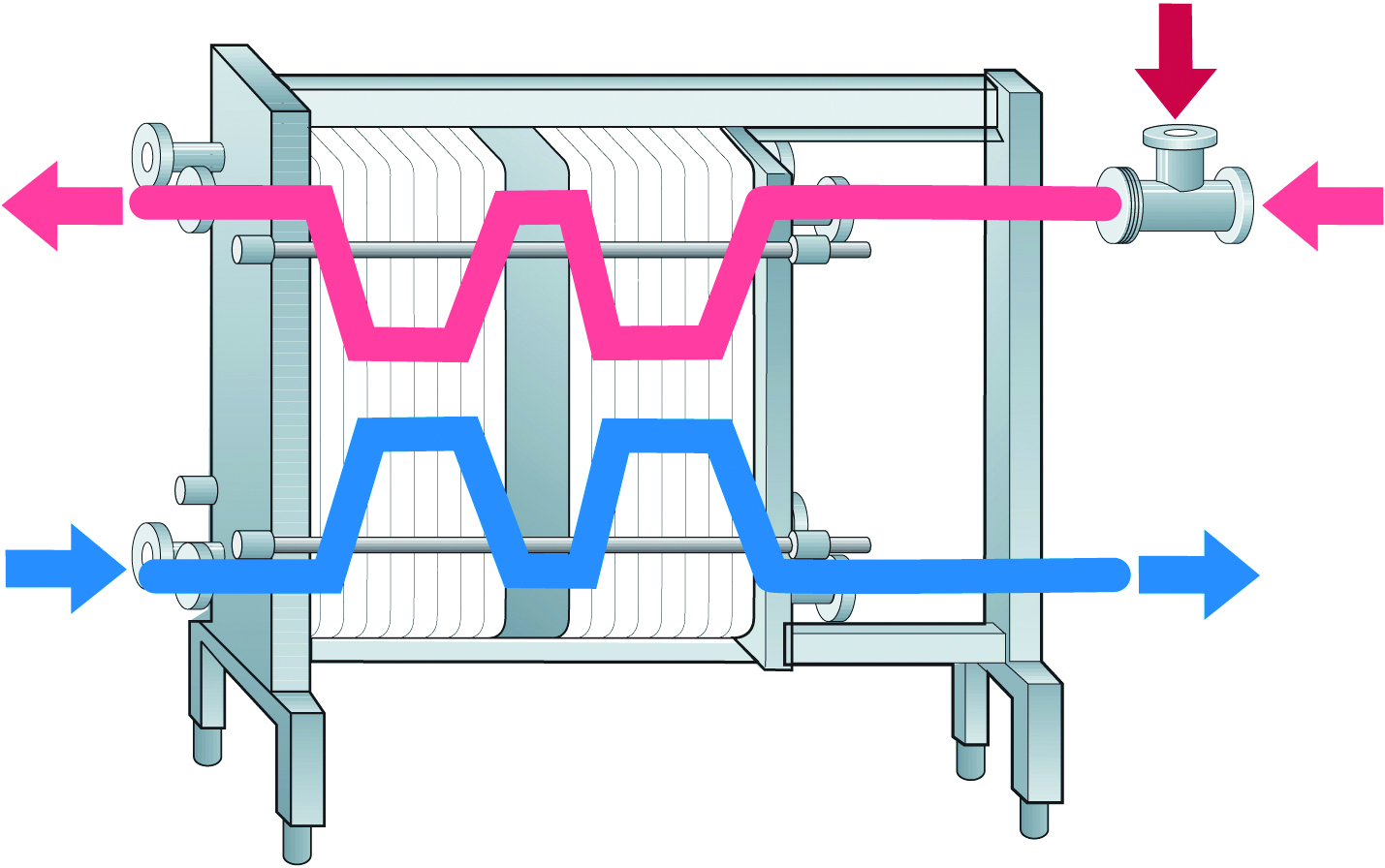

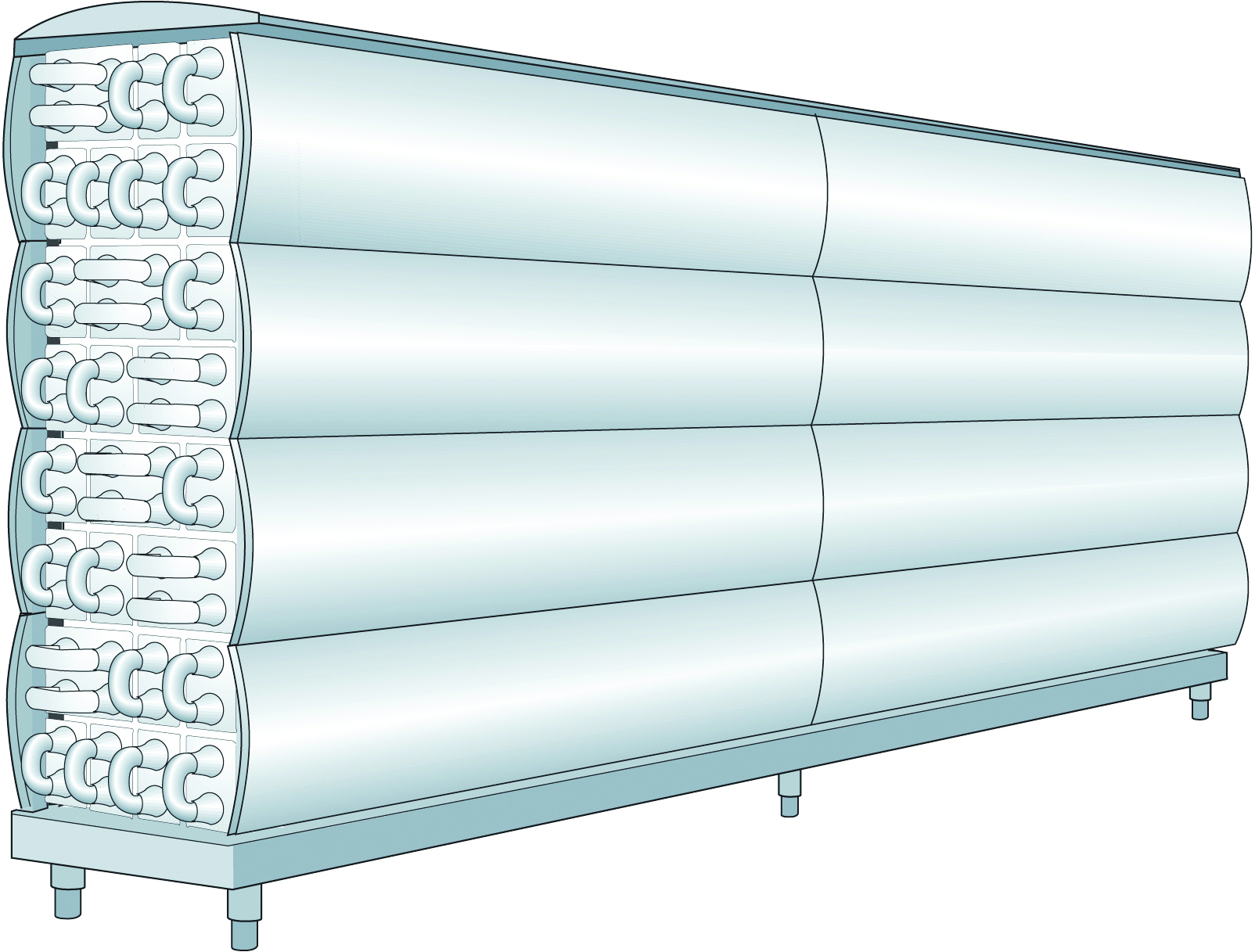

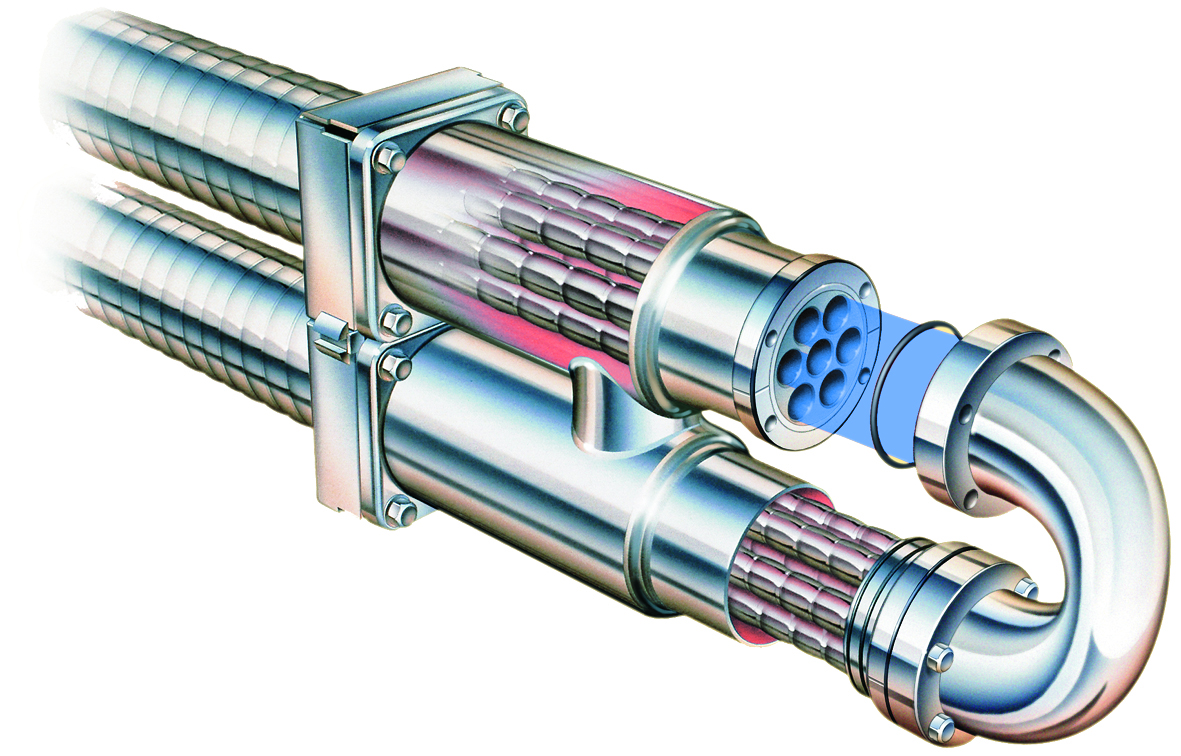

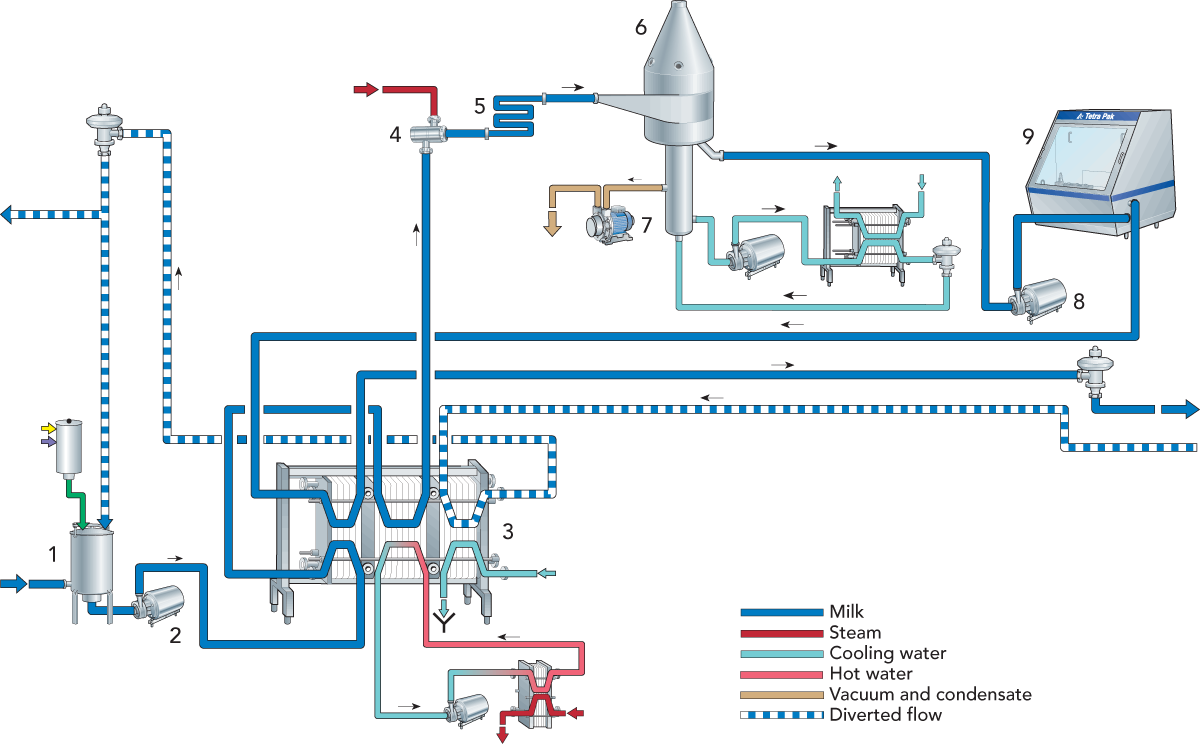

Indirect UHT system

With indirect UHT systems (Figures 11.9 and 11.10), a heat exchange surface separates the product from the heating or cooling media. The heating medium can be either steam or water in a plate or tubular heat exchanger (see Figures 11.11, 11.12, 11.13 and 11.14). Typically, the product enters the sterilizer via a balance inlet tank and a centrifugal feeding pump at 4-25oC. Subsequently, it is heated to 70-75oC when the product is homogenized.

For coconut milk based liquid products, a two-stage homogenization of total pressure ranging from 150-200 bar is often used. The product is then pushed through the remaining equipment for sterilization. Sterilization temperatures are usually 137-145oC. Holding times between 4-15 seconds at the sterilization temperature are common. Alternatively, the coconut milk goes through sterilization first before going into an aseptic downstream homogenizer at 150-200 bar, 70-75oC. Often, downstream (aseptic) homogenization is preferred for coconut milk, as it results in better texture and stability characteristics.

The coconut milk is prone to oxidative damage. In order to lower the air content of the product, deaeration can be introduced prior to upstream homogenization. The degree of deaeration depends on the temperature and vacuum pressure applied in the deaerator.

Indirect systems offer good possibilities for regenerative energy recovery, as the incoming product is heated by the outgoing beverage.

For both plate and tubular (single and multiple tube) systems for commercial production, capacity ranges from 1,000 to 30,000 litres per hour, or even more.

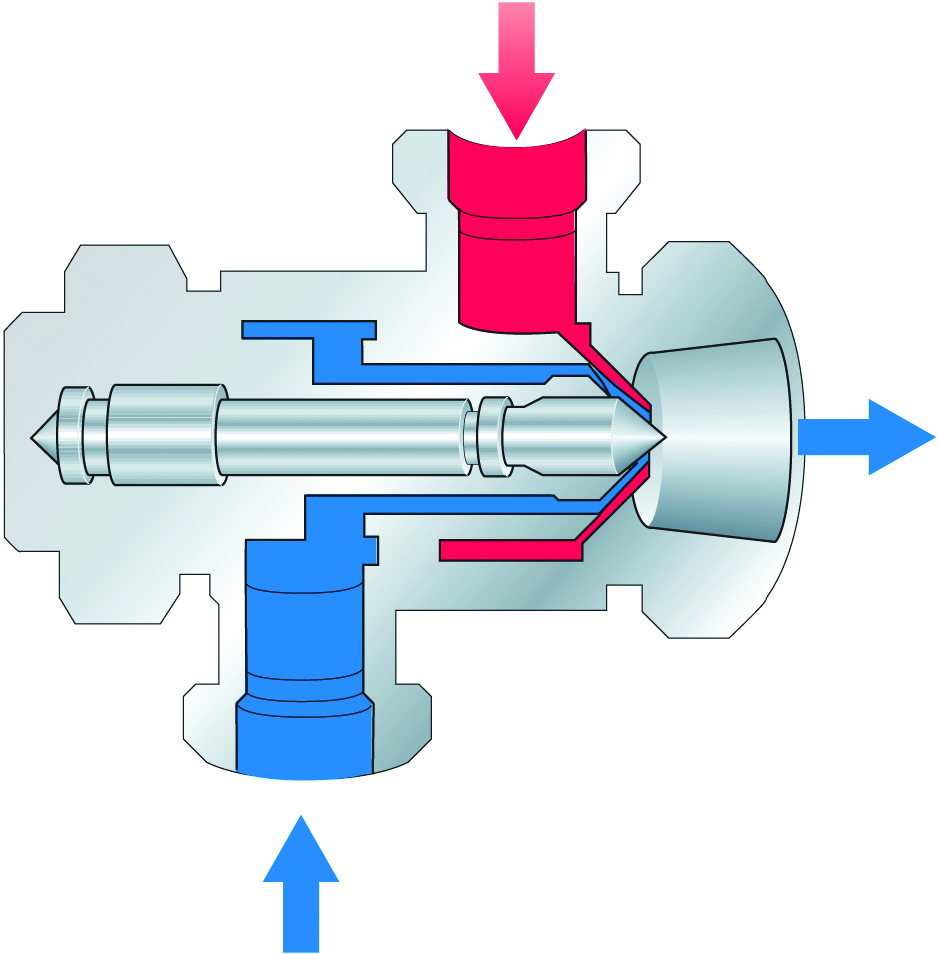

Direct UHT systems feature direct contact between the heating medium and the product. This allows direct steam injection into the product (Figure 11.15).

At a temperature of about 4-15oC, the product enters the sterilizer via a balance inlet tank and a centrifugal feeding pump. It is heated by plate or tubular heat exchangers to about 70-80oC.

At this stage, steam is injected into the product (Figure 11.16), or the product is conveyed into a steam chamber. In infusion systems, the product is infused into a steam chamber so both injection and infusion systems must operate with culinary steam. Steam condensation increases the temperature almost instantaneously to the sterilization temperature, which is typically between 137oC and 145oC. At the sterilisation temperature, the average holding time is 4-15 seconds. In both the injection and infusion processes, water condenses in the product and dilutes it.

Subsequently, equal amounts of water must be removed. The outlet of the holding cell connects to a vacuum chamber. To prevent boiling in the product-holding cell, a sufficient overpressure by a suitable restriction device must be introduced. When exposed to underpressure, the product starts boiling vigorously and steam is flushed off. Careful adjustment of the injection or infusion temperature and the underpressure in the vacuum chamber guarantees a consistent dry matter content of the incoming and outgoing products. As a result, the pressure drops and requires an aseptic transfer pump to be installed for further product transportation.

In order to avoid an accumulation of product in the expansion cooler, both the product feeding pump and the transfer pump at the outlet of the expansion cooler must be carefully matched. The capacity of the transfer extraction pump is often controlled by a sensor immersed in the product, in the vacuum chamber.

Then, cavitation forces during steam condensation destabilize protein and fat. To compensate for this effect, direct heating requires downstream homogenization, which has to be done under aseptic conditions. Homogenization pressures for coconut liquid products are usually 150-200 bar. The homogenizer pushes the product through the final cooling section of the sterilizer, either into an aseptic storage tank or directly into the aseptic filling machine.

In the expansion cooler, water and other volatile compounds are removed from the product. In addition, the vacuum chamber functions as a very effective deaerator removing oxygen and other dissolved gases, including carbon dioxide (CO2). As a consequence, the freezing point of the product increases.

Recently, special UHT heat exchangers have been developed to combine direct and indirect heating processes. In one assembly, tubular heating and steam injection were combined. The product enters at around 4-10oC and is heated to 95oC by tubular heat exchangers. Steam injection raises the temperature instantaneously to 140oC. The product is held at this temperature for a few seconds before it is cooled down. Pre-cooling is performed in a tubular heat exchanger where heat is utilized for regenerative heating and the injected steam is flushed off as a vapour in a vacuum cooler. When temperature drops to 80oC, aseptic homogenization is needed. Subsequently, the product is cooled to ambient temperature and filled aseptically.

Product quality from different UHT systems

Different UHT systems affect the product quality of coconut milk and coconut water (Tables 11.3 and 11.4).