Coconut Food Production

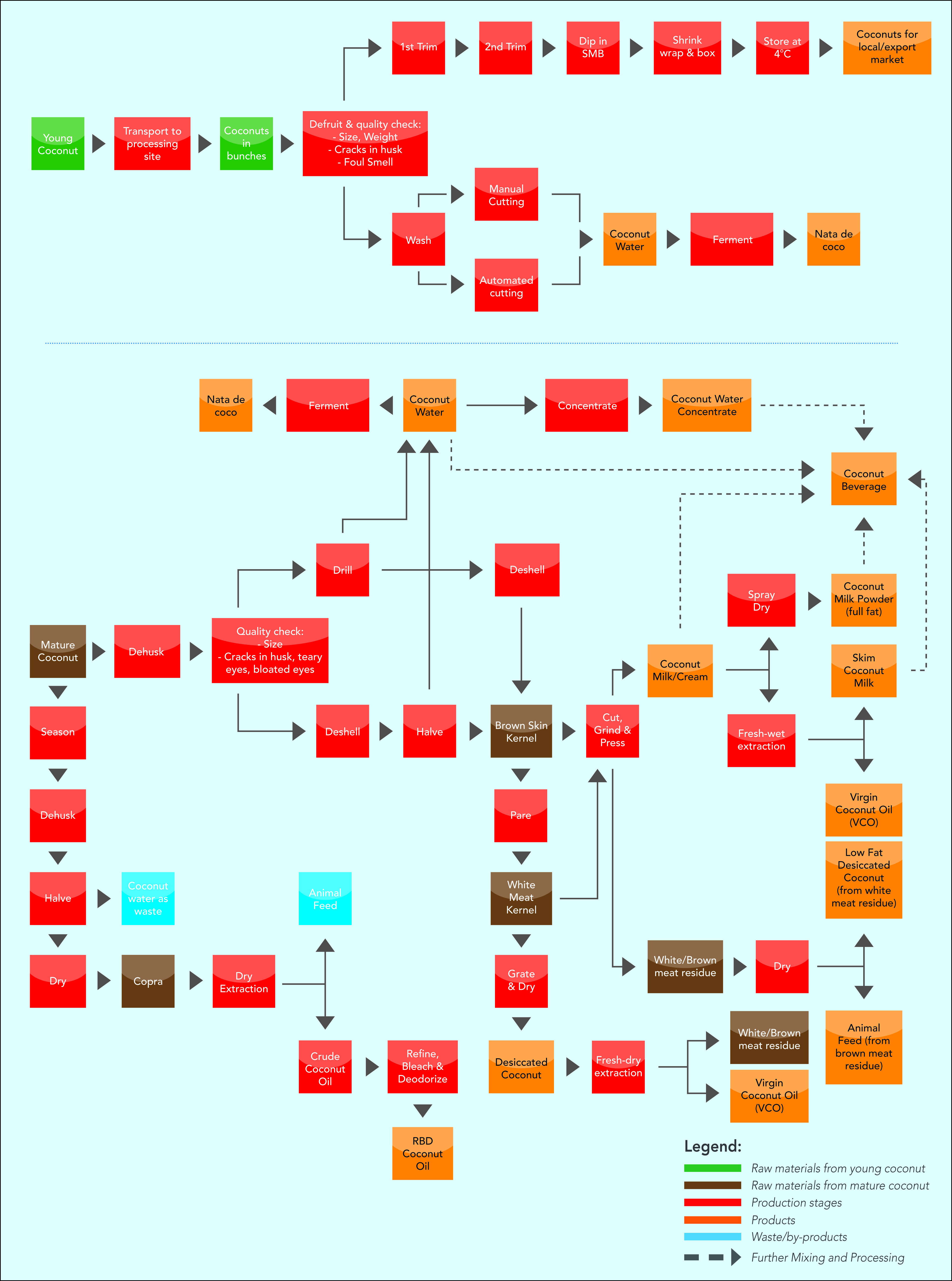

It is popular among Indonesians to say that there is a use for the coconut palm in every day of the year. Indeed, coconuts can be processed into many products. The coconut kernel and water are two edible parts which form the basic ingredient for a variety of coconut products. Figure 6.1 in the next page shows how these products are made through a combination of processes and sometimes, a by- product of each other.

Coconut water

Coconut water is a refreshing and cooling drink. Its sodium and potassium content makes it an ideal drink for rehydration. In a healthy, undamaged coconut, the water is even sterile. During World War II, coconut water was used intravenously to treat patients suffering from blood loss when blood plasma was not available. It is also a ready source of clean drinking water, especially after a natural disaster.

There was little need to develop scientific knowledge on coconut water processing as it was typically consumed fresh from the nut. The science behind coconut water and its characteristics was only required when there was exponential demand from various markets which did not produce enough coconuts. As such, coconut water was extracted, processed, packaged and transported across long distances. This presented new challenges as coconut water reacts quickly once the nut is opened. With the advances in aseptic packaging technology, the shelf life of coconut water can be extended for up to a year. Please refer to Chapter 11 for more details.

Coconut water is harvested from young and mature coconuts. Due to different characteristics of the husk, shell and interior of the coconut, the extraction methods for both types are slightly different. Nevertheless, both types of coconut water can be extracted and processed for packaging. They are drilled into the cavity to obtain the coconut water. Normally, the drilling of a hole occurs at or near one of the three eyes of the coconuts where the shell and flesh is the thinnest or weakest.

Figure 6.1 Integrated Processing of Coconut Products (Flowchart)

Coconut water is also considered a by-product of desiccated coconut or coconut milk production, where the mature coconuts are collected and halved. As consumers increasingly demand the best quality coconut water, manufacturers prefer to drill the mature coconuts instead. This drains the coconut water out by minimizing the contamination of coconut water from the loose soil and fibres from the mature coconut shell.

After extraction, coconut water is filtered. Filtration can be done using a cheese cloth, fine filter or a scrap surface filter. This is especially important for mature coconut water, as dry husk fibres and dirt from the shell of mature nuts can easily get into the coconut water during extraction. After filtration, the coconut water is quickly cooled to retard any deterioration reactions. Then, it is sent for de- oiling (separation), subsequent pasteurization and aseptic packaging. If coconut water is extracted at a location away from the aseptic packaging site, the filtered coconut water can be packed into food grade plastic bags, quickly cooled and transported to downstream processing. Please refer to Chapters 7, 11 and 12 for more details.

Often, it is not commercially viable to transport large amounts of single strength coconut water (92-95% water content) in bulk to markets where coconuts are not readily available. As such, technological advances can concentrate coconut water to higher soluble solid levels of 60-65 °Brix (or 35-40% water content), saving considerable resources on transportation.

To produce coconut water concentrate, fresh coconut water is first passed through a pre-concentration stage of reverse osmosis to increase the total solids. Then, it goes into a multiple effect evaporation stage to increase °Brix levels. Usually, the product is concentrated to 60-65 °Brix and packed into 200 kg plastic bags in drums for bulk transportation under ambient conditions. At this high °Brix level, the concentration of coconut water is somewhat self- preserving. Upon arrival, it is recommended that the concentrate be stored at -18°C for use up to two years. To reconstitute the coconut water concentrate to single strength coconut water for further aseptic processing and packaging, concentrate is blended with water at appropriate proportions to get the desired °Brix level.

Coconut milk and cream

Coconut milk and cream is produced from 10-13 months old mature coconuts when the kernel is hard and thick. They are natural oil-in-water emulsions extracted from the mature coconut kernel.

The difference between coconut milk and cream is the amount of fat in the products. It is important to categorize coconut milk products according to fat content. The Codex Standards for Aqueous coconut products states that coconut milk should contain at least 10% fat, 2.7% non-fat solids, and 12.7-25.3% total solids. While coconut cream should contain at least 20% fat, 5.4% non-fat solids and 25.4-37.3% fat (Table 6.1).

To extract coconut milk and cream, mature coconuts must first be dehusked and deshelled. The layer of brown skin is also pared off to get a layer of white kernel, as the skin can impart a brown colour and slightly bitter taste to extracted coconut milk. The kernel is then washed, drained and grated by machine into kernel flakes. Thereafter, it is mechanically pressed to extract the coconut milk.

To extract coconut milk at home, consumers usually buy grated kernel and mix with water, as water is especially helpful in manual extraction. The mixture is then poured into a sieve or a muslin cloth where it is squeezed by hand. This extraction can be repeated a few times by adding water to maximize the soluble material extracted from the kernel. With each subsequent extraction, the oil level of the resulting coconut milk decreases, which varies according to the amount of water added to the mixture. Extracted coconut milk can either be used immediately or left to stand. Upon standing, it separates into two distinct layers – the oil-rich phase (cream) on top, and the water- rich (“whey”) below.

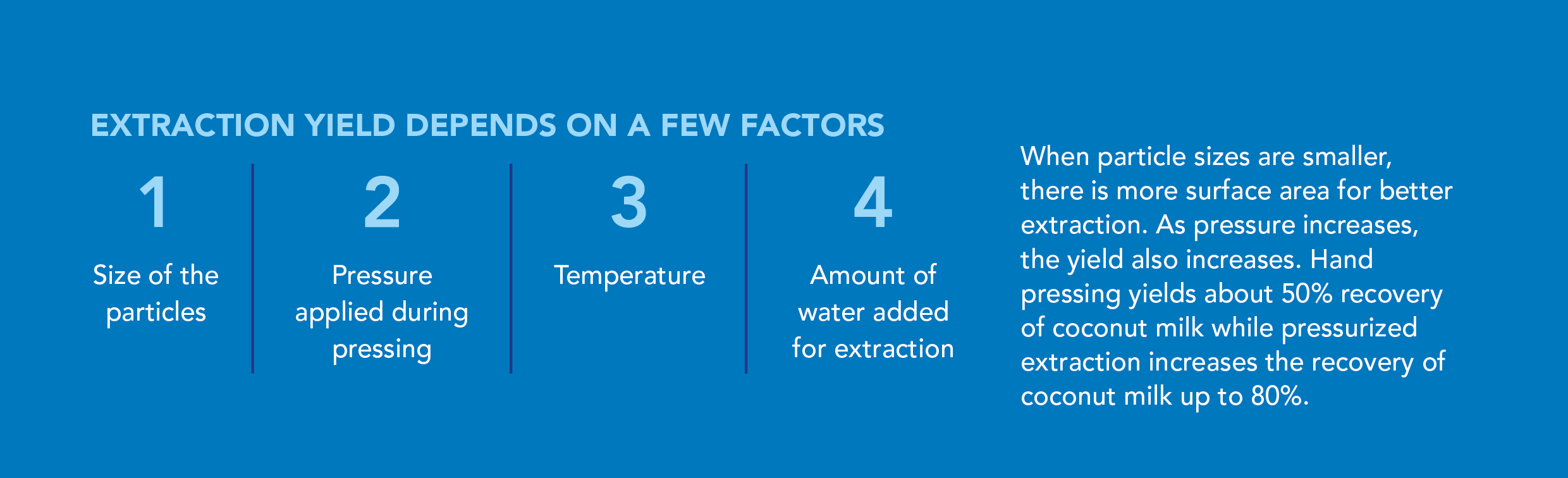

To extract coconut milk for industrial manufacturing purposes, mature coconuts go through deshelling and paring. Pieces of kernels are then sent into industrial scale cutters and grinders. In integrated plants, the by-product coconut water is also collected by drilling the coconut before deshelling, or halving the coconuts after deshelling. Next, grated coconut kernel then goes into a series of screw presses to extract coconut milk. The residual kernel from this first press is then mixed with water before it is pressed again to increase extraction yield. Extraction yield can be represented by oil recovery yield.

After extraction, coconut milk is filtered to remove large contaminants. It can then be standardized to a pre-determined level of fat and blended with other ingredients. Finally, coconut milk is pasteurized and aseptically filled into packages for transportation to global markets.

The composition of coconut milk can be found in Table 6.2.

Coconut milk beverages

Coconut milk drinks are healthy beverages. Unless it contains spray- dried coconut powder and skim milk, it is naturally cholesterol free and contains healthy medium chain fatty acids. Coconut milk beverages also provide an alternative to dairy products for lactose intolerant consumers.

In general, coconut milk beverages are not readily available in many countries where there is little or no coconut production of their own. As a perishable product, coconut milk beverage has limited shelf life and is easily attacked by microorganisms and bacterial enzymes when exposed to the environment.

To prevent this, recombination is an alternative method of supplying a product that closely resembles fresh coconut milk to markets where the genuine article is not available. Through recombination, coconut milk beverages can be produced from coconut milk, coconut milk powder or coconut water. It can also be produced from a combination of the three, with additional ingredients like juices, flavourings and fortifications.

Production methods and factors affecting coconut milk beverages are discussed in Chapters 8, 9, 11 and 12.

Coconut oil

Coconut oil is one of the main products traditionally derived from the coconut kernel. It is a mixture of chemical compounds called triglycerides that are compounds made up of fatty acids and glycerol. Coconut oil is rich in saturated fatty acids and low in unsaturated fatty acids. The different fatty acids present in coconut can range from C6-C18 carbon atom chains.

Coconut oil processing methods or technologies are classified into two major types based on copra or fresh coconut kernel used. The oil extraction technology, which starts with copra as the raw material, is commonly known as the dry process. While the method that uses fresh coconuts as starting material is generally called the fresh-wet or fresh-dry process. Based on different separation methods, coconut oil can be classified into two types – RBD coconut oil and virgin coconut oil (VCO). The former is refined, bleached and deodorized (RBD) from dry extraction, while the latter is produced by fresh-wet and fresh-dry extractions.

Fatty acids composition between RBD coconut oil and VCO are similar, with the VCO regulation largely falling within the Codex specifications for coconut oil (see Table 6.3 and 6.4).

RBD coconut oil

Coconut kernel is converted into copra before it is expelled and refined for oil production. This is done by first drying the kernel under the sun in an oil mill. To extract coconut oil for extensive food and industrial purposes, dry processing is used. Clean, ground and steamed copra is first pressed by wedge press, screw press or hydraulic press to obtain coconut oil, which then goes through the refining, bleaching, and deodorizing (RBD) processes. During the RBD process, heat is applied to deodorization, which is carried out at high temperatures between 204-245°C.

During dry processing, oil is extracted by two methods – mechanically pressing or using solvents. For copra with high oil content, mechanical extraction is efficient and economical. For oil seed that requires further oil extraction from copra cake, the solvent extraction method is more suitable as it uses sophisticated equipment in large-scale operations.

When oil is extracted with the mechanical method, low-pressure expellers are used. The pre-treated copra is continuously moved under increasing pressure by a worm screw in a horizontal cage of barrel made of metal bars to expel out the crude coconut oil. What is left behind is the copra cake, which can then undergo solvent extraction to extract higher oil yields. By combining both methods, oil yields are more efficient and economical than just using either one of them.

When oil is extracted with the solvent method, hexane is used to dissolve the oil in copra or copra cake. The copra is steeped in hexane and allowed to percolate continuously through a bed of copra. In general, the copra moves in one direction while the solvent- oil mixture moves in the opposite direction.

Virgin coconut oil (VCO)

When fresh-wet extraction is used, VCO is obtained from coconut milk. It can be consumed in its natural state without further processing (e.g. RBD process). VCO mainly consists of medium chain triglycerides which are resistant to peroxidation. The fatty acids in VCO are distinct from animal fats which contain mainly long chain saturated fatty acids. As such, it is colourless, free of sediment and a rancid odour. It also spots a naturally fresh coconut scent.

To extract VCO on a small scale, the biochemical method is used. This is based on the action of microorganisms on coconut milk, which results in the liberation of coconut oil from coconut milk emulsion. It is a simple and economical process that requires only 48-72 hours to separate the oil from the whey and protein portion of coconut milk. The enzymes and acids produced by the microorganisms trigger the separation of oil from the coconut milk. Water-white, rancid-resistant, and sweet-smelling oil is produced by the action of Leuconostoc citrovorum, Streptococcus lactis, and Bacillus subtilis. A pure culture of Lactobacillus plantarum can also be used. Finally, the VCO extracted is about 90.2% oil.

Through fresh-dry extraction, VCO is produced from fresh coconut kernel. This is first dehydrated to form desiccated coconut, which then goes into high pressure expellers to extract the oil. The oil then goes through a stage of setting and filtration to polish the oil into water-like clarity.

In terms of physicochemical properties, VCO does not vary much from RBD coconut oil. Nevertheless, Table 6.5 shows some comparisons between VCO and RBD coconut oil.

Coconut flour

Coconut flour is a screened food grade product obtained after drying, expelling and extracting most of the oil or milk from sound coconut meat. It is cream coloured and less white than all-purpose flour. With a slightly nutty odour, it tastes almost bland, due to its reduced fat content. It is classified according to fat (low, medium and high), protein (high protein) and fibre (high fibre) (see Table 6.6).

Coconut milk powder

Coconut milk powder is spray-dried coconut milk. Similar to instant milk powder, it is white in colour, free flowing and easily dispersed in water. It also has an acceptable coconut flavour.

Powdered coconut milk contains about 61% oil, 27% carbohydrates, 7% protein, 1.8% ash, 0.2-0.8% moisture and 0.02% crude fibre. It can be easily reconstituted into coconut milk by adding water and used directly in food recipes.

For coconut milk to be spray-dried into powder, it must first be mixed with maltodextrin and casein (sodium caseinate or skim milk). This is because maltodextrin is required in the spray drying operation, while casein prevents lumping of the coconut milk powder due to its high fat content reaching up to 79%. With casein, the protein encapsulates the small oil droplets which prevents them from lumping together, forming a powdery product.

Desiccated coconut

Desiccated coconut is produced from the kernel of fully matured coconuts. Rich in oil and taste, it is a commonly found ingredient in the confectionary industry for many baked foods, chocolates, candies and even ice cream. For over 70 years, it is a traditionally exported commodity, and is one of the most important commercial products from coconut. As it is made directly from coconut meat, desiccated coconut retains the original oil and protein of a fresh mature coconut.

To produce desiccated coconut, fresh mature coconut kernel is first pared down to remove the brown skin and any infected meat. The white kernel is then rinsed and sterilized to eliminate bacteria, including Salmonella which cases food poisoning.

To sterilize, the meat can be pasteurized at 80-90°C in 2% sodium metabisulphite solution for 20 minutes. It can also be passed through a large tank containing boiling water or subjecting the pieces of meat to live steam in stainless steel blanchers at 80°C for five minutes. The pasteurized kernel is then sent to the disintegrators or cutters where it is cut and then shredded into a fine, wet meal. The cutters have adjustable provisions so that shredded coconut meat of different sizes can be obtained.

The wet meal is then dried by spreading it out on trays which are then mounted in tiers in a hot-air drier. It can also be dried in a continuous dryer with two stages where the material is turned over from the first to the second stage. This is done until it reaches a low moisture content of about 2.5-3.5%. Different sizes of desiccated coconut is then mixed and conveyed to a sieving machine, where different particle sizes are separated and bagged into 50kg bags.

Alternatively, desiccated coconut is produced from the by-product of coconut milk production. The wet meal that is left after coconut milk has been extracted from the wet kernel is still a good source of fibre, protein, and oil. It can go through further shredding, or go straight into the dryer and dried until it reaches a low moisture content. As a result, such desiccated coconut has lower fat levels and can be classified as defatted desiccated coconut.

In general, there are four different grades of desiccated coconut classified according to coarse, medium, fine and superfine sizes.

The required specifications for desiccated coconut are not uniform across all markets. Each exporter or importer has his own standards and requirements. The Codex definition on desiccated coconut is seen in Table 6.7.

In some markets where sulphite treatment is carried out, it is specified by some buyers that the residual level of sulphite is no more than 15-100ppm, or sulphite-free.

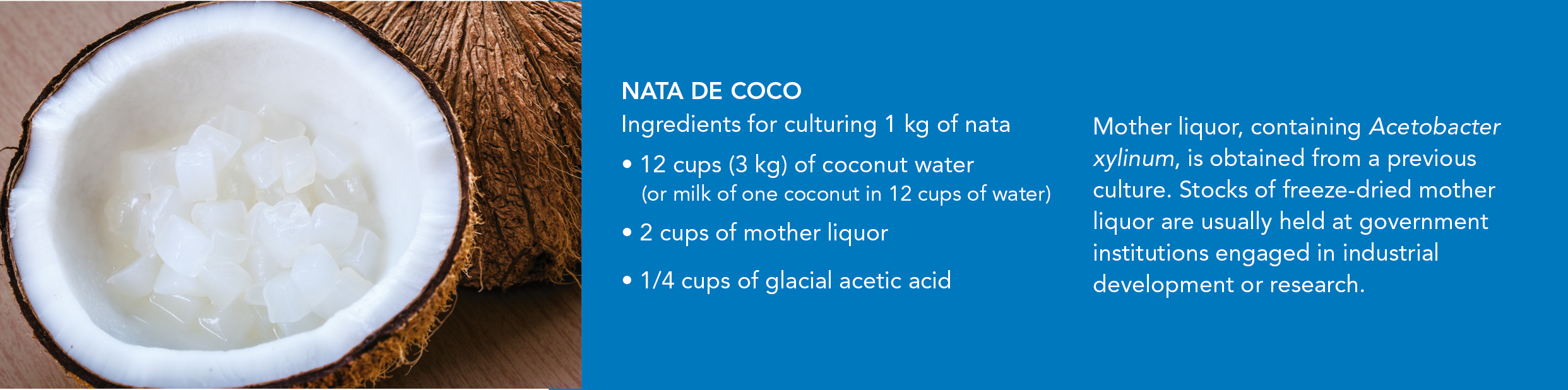

Nata de coco

Nata de coco is a gelatinous dessert with a clear, smooth and chewy texture. It is composed of cellulose produced by the action of an acidic medium called Acetobacter xylinum on coconut water or diluted coconut milk. ‘Nata’, when formed, is sweetened by cooking in thick sugar syrup. After production, nata de coco is bottled for local consumption and exported to the Philippines, Thailand, Indonesia, and Sri Lanka.

First, coconut water or diluted coconut milk is filtered and boiled to kill off contaminants. Next, the filtered mixture is cooled. Then, a cup of sugar is dissolved and added into the mixture along with mother liquor and acetic acid. Finally, the mixture is poured into culture jars to a height of 60 mm, covered with clean paper and incubated between 23-32°C, optimally at 28°C. The jars are left undisturbed, so that the nata formed at the surface will sink to the bottom.

After eight to 10 days, nata is picked out with a clean fork when it is about 25 mm thick. Care should be taken not to contaminate the mother liquid below the nata formation, as it will be used again as a culture in the next production of nata. It is then cleaned by removing the creamy, acid formation at the bottom and cut into squares of about 20 mm. It is then washed and boiled for one minute in an open pan, drained, and soaked in water that is changed constantly. This is repeated until the acidic taste is removed.

Finally, the nata is drained over a two hour period. Sugar syrup is prepared using two cups of sugar with one cup of water. Last but not least, the product is kept overnight when the nata and colouring are added. The next day, the nata is cooked until the gummy texture is removed and becomes relatively transparent. Flavouring is added and nata bottles are filled with 75% nata and 25% sugar syrup. For packaging, the bottles are tightly sealed with seal caps and processed in boiling water for 30 minutes, then dried and cooled before storage.

When produced on an industrial scale, large, 200 litre drums are used to mix the acid, coconut water or diluted coconut milk with mother liquor and sugar. Nata is also set in moulding containers about 2-3 cm thick.

Recipes

Beverages

(2 servings)

Coconut water and milk can be combined with other ingredients in cooking. Here are some delicious in-home recipes for reference.

Coconut milk beverage

Delicious alternative to dairy milk

- 1-2 tablespoon coconut milk or cream

- 1 cup coconut water

- Sugar and 1 teaspoon chocolate powder to taste

Stir all ingredients well. Best served chilled.

Hangover cure

Hydrates the body quickly and safely

- 1 green tea bag

- 2 cups coconut water

Bring coconut water to boil in a saucepan. Take off heat.

Steep the green tea bag in hot coconut water for 3-4 minutes.

Blend well and serve immediately.

Green helper

Balances an “over-acidic” body

- 1 medium cucumber

- 1 large red apple

- 2 cups coconut water

- 6 carrots

- 6 stalks celery

- Handful of ice cubes

Run the cucumber, red apple, carrots and celery stalks through the juicer.

Mix fresh juices well with coconut water. Add ice and serve immediately.

Coconut water and watermelon cooler

Rehydrates and cools on a hot day

- 1 cup coconut water

- 1 fresh lime, juiced

- 1 tablespoon honey

- 2 cups fresh watermelon chunks without seeds

Blend until smooth and serve immediately.

Coconut soy beverage

Delicious alternative to dairy milk

- 1-2 tablespoon of coconut milk

- 1 cup of soy milk

- Sugar or honey to taste

Blend all and serve chilled immediately.

Coconut and cranberry flush

Maintains good urinary health

- 2 cups coconut water

- 2 cups cranberry juice

Blend well and serve immediately.

Strawberries and Pineapple smoothie

Healthy liquid breakfast packed with antioxidants and other immune-boosting properties

- 1 cup coconut water

- 1 cup pineapple chunks

- 1 teaspoon honey (more to taste)

- 2 cups halved strawberries

- 2 cups crushed ice

- Some cubed coconut kernel

Combine all ingredients in blender and process until smooth.

Divide smoothie between 2 glasses and serve chilled.

Meals

(4 to 6 servings)

Chicken and barley soup

Nourishes the soul

- 1⁄2 cup pearl barley

- 1 chicken, cut into large pieces

- 1 onion, chopped

- 2 large carrots, chopped

- 2 stalks leek, chopped

- 8 cups coconut water

- Powdered chicken stock, to taste

- Sea salt flakes and freshly ground pepper, to taste

- Chopped parsley for garnishing

Fill a large pot with coconut water and add the chicken pieces. Cook on low heat until chicken is tender.

Remove chicken from broth and set aside until cool enough to handle.

Cool broth and skim off chicken fat. Remove meat from bones; discard bones and shred meat. Set aside.

Add vegetables and barley to the broth and bring to a boil.

Reduce heat; cover and simmer for 1 hour or until vegetables and barley are tender.

Add shredded chicken to broth during the last 10 minutes of cooking.

Season with salt and pepper to taste. Serve hot with chopped parsley as garnish.

Chicken curry

Satisfies a hearty appetite

- 1⁄2 cup coconut milk

- 1⁄2 onion, diced

- 1 oz (25 g) curry powder for meat

- 1 big tomato, cut into wedges, optional

- 1 1⁄2 lbs chicken, chopped into pieces

- 2 small potatoes, peeled and cut into wedges

- 2 tablespoon oil

- 3 cups water

- 4 hard-boiled eggs, optional

- Salt to taste

Heat oil in a pot. Stir-fry onions until aromatic, add curry powder.

Stir a few times, then add the chicken, stir to combine for about 1 minute. Add the water into the pot and bring it to boil.

Lower the heat, add tomatoes, potatoes and eggs.

Cover the pot, simmer for 30-45 minutes or until chicken is tender.

Add coconut milk and salt to taste, simmer for another 5 minutes.

Dish out and serve immediately with steamed rice.

Desserts

(2 servings)

Coconut jelly

Healthy, low-fat sweet indulgence

- 3 cups coconut water

- 31⁄2 tablespoon gelatine

- 11⁄2 cup sugar

- 1 tablespoon lemon juice

- 1⁄2 cup coconut milk to coat

- 1⁄2 cup melted coconut palm sugar (Gula Melaka) to coat

- 1 teaspoon of toasted grated coconut

Dissolve sugar in 2 cups of coconut water

Heat 1 cup coconut water over low heat, add in gelatine and mix until fully dissolved

Strain coconut water-gelatine blend into coconut water sugar blend.

Add in lemon juice and gently mix.

Pour into individual moulds and chill it with the required time.

Serve with freshly squeezed coconut milk and melted palm sugar (or Gula Melaka) drizzled over

Garnish with toasted grated coconut to own preference.

Alternatively, substitute the liquid used to make your favourite jelly recipe with coconut water.

Kaya

Coconut egg jam

- 1⁄2 cup coconut cream

- 3⁄4 cup coconut milk

- 11⁄2 tablespoons corn starch

- 11⁄2 tablespoons water

- 3 pandan leaves, tied into a knot

- 4-5 eggs

- 50-75g sugar, dissolved to make caramel 200g sugar

Crack the eggs into a big bowl, whisk well with coconut cream, coconut milk, and sugar.

Filter the mixture with a strainer and transfer the egg mixture into a sauce pan.

Add pandan leaves into egg mixture and turn on the heat to medium low.

Using a wood spatula or a pair of wooden chopsticks to stir the mixture until they are cooked for about 20 minutes.

To thicken the kaya, add corn starch mixture and stir. At the same time, heat the sugar in a sauce pan until it melts into caramel.

Add the caramel into the kaya, stir to combine. The colour of the kaya should be golden brown.

Let the kaya cool and discard pandan leaves.

Blend the mixture until a silky smooth consistency is reached.

Keep refrigerated and use within a week.