Chilled Coconut Liquid Products

Pasteurization is a mild heat process that destroys undesirable organisms, including vegetative disease-causing ones. It effectively extends the shelf life of the product. In order to ensure product safety and quality for consumers, there must be an understanding of the many variables involved in pasteurization, including increased hygiene conditions, packaging and chilled distribution.

Processing chilled coconut liquid products

Pasteurization is a mild heat process that destroys undesirable organisms, including vegetative disease-causing ones. The process is named after the French scientist, Louis Pasteur, who discovered in the 1860s that undesired fermentation could be prevented in wine and beer by heating it to 57°C for a few minutes.

Pasteurization eliminates vegetative bacteria in coconut liquid products to ensure food safety, and maintains rigid quality control over both raw and finished products. It can be categorized as low temperature long time (LTLT) pasteurization, high temperature short time (HTST) pasteurization and ultrapasteurization. Each type of treatment requires a specific type of packaging to maximize its effect. Table 12.1 shows the characteristics of different types of heat treatment.

Coconut liquid products are ideal media for bacterial growth and require some form of heat processing for long-term storage.

As such, coconut beverages and coconut milk can be quickly processed using pasteurization. This also maintains a rigid quality control over raw and finished products. The process involves mildly heating coconut liquid products, which results in an increased refrigerated shelf life. Pasteurization eliminates vegetative bacteria in coconut liquid products. Overall, the harmful impact of pasteurization on coconut liquid product quality is relatively mild. Although bacterial spores and some heat-resistant, non-disease causing microorganisms can survive the pasteurization process, the total microbial load is substantially reduced.

Low temperature, long time (LTLT) pasteurization

The original heat treatment for dairy milk was a batch process in which dairy milk was heated to 63°C in open vats and held at that temperature for 30 minutes. This method is called the LTLT or holder method. Today, coconut liquid products are more commonly treated in continuous processes like HTST pasteurization and UHT treatment.

High temperature, short time (HTST) pasteurization

In HTST method, the actual time and temperature combination varies according to the quality of the coconut base, the type of product treated, and the required keeping qualities of the product.

Ultrapasteurization

Ultrapasteurization is an extended heat treatment, which aims to extend the coconut liquid products shelf life beyond that of a typical pasteurized coconut beverage. Some manufacturers aim to put two extra days on top of the typical shelf life of a pasteurized coconut beverage, while others aim for an additional 30-40 days.

Ultrapasteurization conditions fall between the conditions needed for normal pasteurization and ultra-high temperature treatment. This treatment can vary in different countries, although generally, the product is heated to between 125-135°C for 0.5-4 seconds. Ultrapasteurization is frequently used in the United States and the European Union. In the United States, the common treatment is 138°C for two seconds while for Europe, it is 127°C for two seconds. This process is also known as high temperature pasteurization in some countries.

Extended Shelf Life (ESL) is a general term used for ultrapasteurized products which have been given improved keeping qualities. Thus, they are able to retain good quality up to 7°C storage temperature. An ESL coconut beverage has an extended shelf life beyond that of its traditionally pasteurized counterpart. ESL beverages must still be kept refrigerated during distribution.

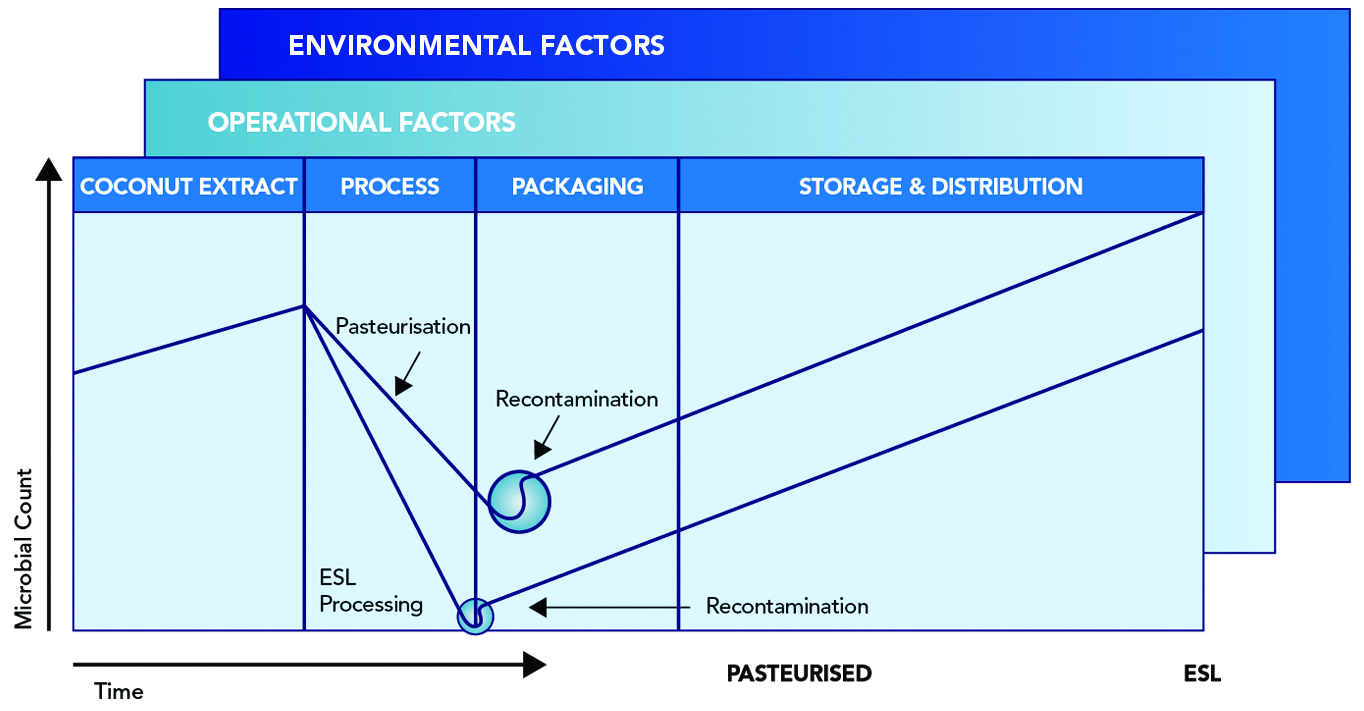

The fundamental principle behind ESL technology is the reduction of reinfection sources during processing and packaging. This requires extremely high levels of production hygiene and low distribution temperature. The lower the temperature, the longer the shelf life. Ideally, coconut beverages like coconut milk should be transported at 4°C, at which the product quality and safety is best maintained (Tan et al., 2015).

Ultrapasteurization can be carried out through direct or indirect heat processing. Direct heat processing is most commonly used as it results in a better sensory quality in the finished product. However, during processing, high heat load increases the risk of heat-induced flavour changes in coconut liquid products, which can be reduced by process and line optimisation. All in all, an ultrapasteurized coconut beverage tends to be safer and of better quality compared to a normally pasteurized coconut beverage. This is mainly due to production in a more hygienic and tightly controlled environment.

Shelf life of ultrapasteurized coconut liquid products

Three different types of laminated carton packaging material

* LDPE: Low Density Polyethylene

** EVOH: Ethylene Vinly Alcohol

Type 1: Economical non-oxygen barrier material. Metallized finish is available on the print side for non-barrier materials.

Type 2: Non-foil oxygen barrier material for oxygen sensitive products. Metallized finish is available on the print side for plastic barrier materials.

Type 3: Highest oxygen barrier with aluminium foil, for longest shelf life of oxygen sensitive material.

For pasteurized coconut liquid products and most pasteurized low acid products, the limiting factor of shelf life is microbiological activity. Ultrapasteurization is able to extend product shelf life, provided the storage conditions are appropriate. Factors affecting the shelf life of ultrapasteurized coconut liquid products include temperature, time, oxygen and moisture. Excessive quantities of these elements cause a loss in nutritional value, producing off- flavours, odours, and rancidity.

The packaging material used also determines the shelf life of the coconut liquid products. There are three types of laminated carton packaging material (Figure 12.1). Due to barrier properties, the packaging material is able to protect the contents against the transfer of gases, flavour compounds, light and microorganisms into the package. In addition, the packaging material used for ultrapasteurized coconut beverages is disinfected, unlike that of pasteurized coconut beverages.

The quality of ultrapasteurized coconut liquid products depends on factors like the quality of the raw material, the processing and storage procedures, packaging, plant hygiene and local distribution conditions. It is important to consider all factors from the raw material stage to delivery on the retail shelf and consumption.

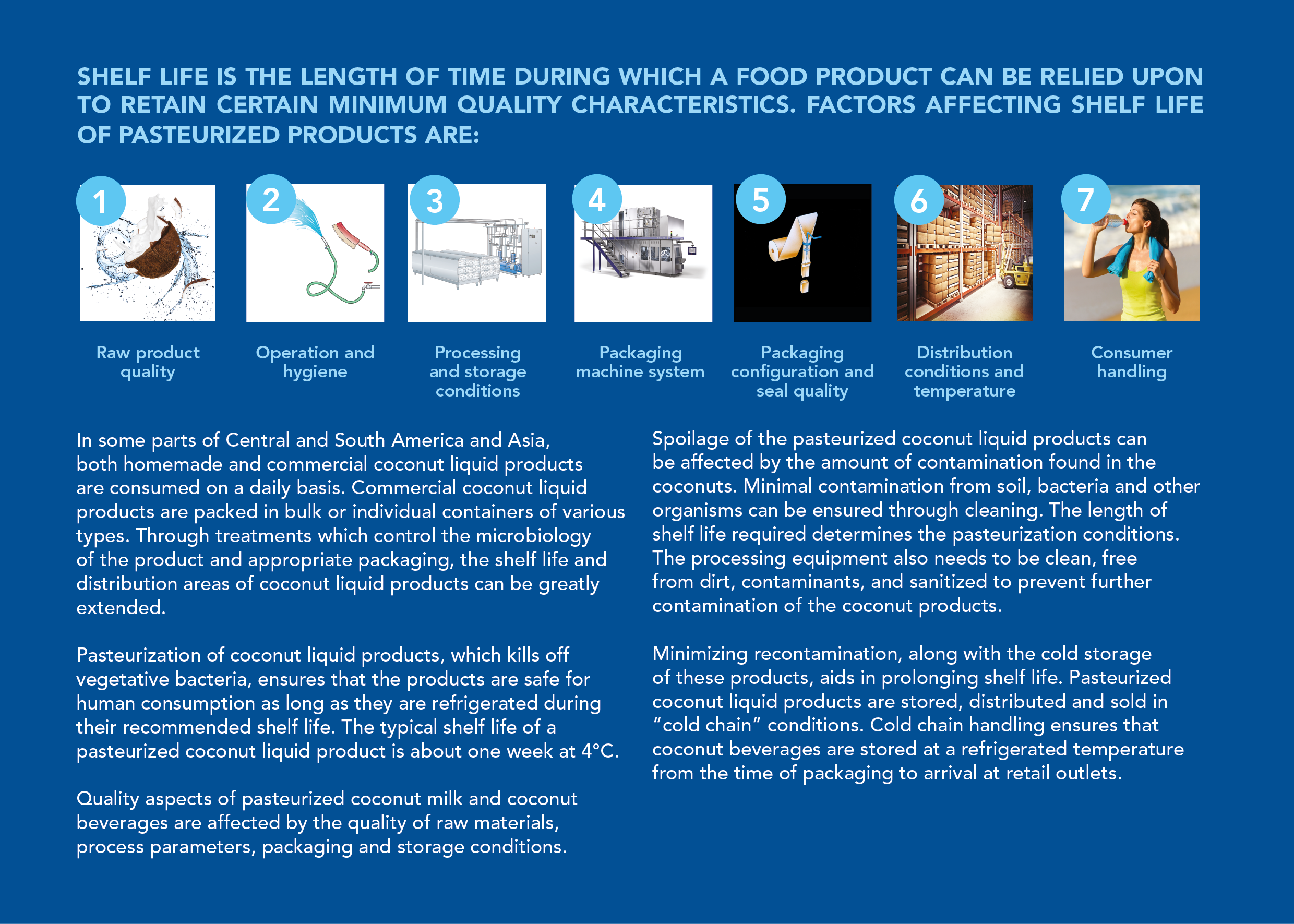

The fundamental principle of extended shelf life processing is to minimize microbial load and recontamination (Figure 12.2). This can be achieved by careful consideration of:

During processing, ultrapasteurization is employed for ESL beverages as it reduces the microbial load to a much greater degree than pasteurization.

Strict hygiene conditions are employed in the processing of ESL beverages. These conditions provide more protection against recontamination from transfer of the product to the filler and the filling environment. In effect, the quality of coconut liquid products fed to the filler is largely maintained through such conditions, and a reduced microbial load is achieved, compared to pasteurized coconut liquid products.

The extended shelf life concept does not merely include the extension of an end product shelf life. The primary advantages offered by the extended shelf life concept are based on improvements in hygiene over the entire chain of production from the extraction of coconut milk and water, processing and filling, to chilled chain distribution.

Through improved product quality and safety, the possibilities of geographic expansion, development of larger markets and production and distribution efficiency are increased. As discussed, the extended shelf life concept involves many factors. The end product quality is the composite result of many variable factors along the entire chain of production, which begins with the quality of the raw coconut material and ends with the quality of the chilled distribution chain. In order to quantify the end product quality and safety, there must be understanding of the many variables that affect product quality.

The factors affecting ultrapasteurized coconut liquid products’ quality, safety and shelf life can be broadly categorized as operational, environmental and technological factors (Table 12.2).

Often only technological factors are considered in shelf life and food safety issues. While equipment continues to be an important factor, there is also a need for increased awareness of the role of the operating environment and the level of skill required by the equipment operator. A balanced approach will ensure a stable foundation for the sustained production of safe and high quality coconut beverages.

Distributing and packaging chilled coconut liquid products

The primary objective of chilled distribution is to reduce or eliminate microbial activity and growth when the product is being stored or distributed. This is done through chilling or reduction of the product temperature, followed by refrigerated storage. The process also aims to extend shelf life. Ultrapasteurized or ESL products are clearly distinguishable from UHT products when it comes to distribution and merchandizing. From the consumers’ perspective, ESL coconut beverages will always be judged by the level of pasteurized coconut beverages as they are merchandized from the same refrigerated section in supermarkets.

Both traditionally pasteurized and ultrapasteurized coconut liquid products are distributed in all types of packages. They must be stored under refrigeration. Through careful handling, essential nutrients and original flavours are preserved in the products. Different packaging materials and containers are used for different products. These are influenced by processing operations undertaken prior to packaging.

The packaging material is selected to maintain the desirable product characteristics as established by the manufacturing process, and to achieve the desired shelf life. Both container type and packaging material can vary. Packaging material used for packing ESL coconut beverages is disinfected with hydrogen peroxide to reduce microbial load. This is unlike the packaging material used for traditionally pasteurized coconut liquid products. Package integrity and stability should be reinforced to ensure product quality during an extended period in a moist and cold environment. General handling and physical damage of the packaging must also be kept to a minimum to ensure package integrity.