Harvesting and Post-harvest Management

Harvesting

Coconut palms are productive throughout the year. However, the yield may vary from season to season. Almost on a monthly basis, a normal bearing coconut palm usually produces one harvestable bunch. On an annual basis, the number of bunches harvested per palm reaches about 14 from Tall varieties and 16 from Dwarf trees.

However, due to practical economic reasons, harvesting for copra production usually takes place every 45-90 days. Instead of harvesting on a monthly basis, this allows them to collect a few bunches, ranging from 10-13 months old, all at one go.

Frequency and amount

A bunch of coconuts from each tree has five to 15 nuts. It can be harvested every month from a coconut palm. To economise, farmers usually yield two to three bunches from each tree. This occurs every harvest cycle, which ranges between 45-60, or 75-90 days. On average, 10-45 nuts can be collected from each coconut tree at various maturity stages every harvest cycle. In order to yield a good number of mature nuts with high copra and oil recovery, the Asian and Pacific Coconut Community (APCC) recommends that each harvest takes place in 45-day harvest cycles.

Methods

The methods of harvesting coconuts vary from country to country, sometimes even among provinces within the same country. Nevertheless, the two most common methods of harvesting coconuts are the pole and climbing methods. In others like Papua New Guinea, the coconuts are left to fall to the ground and collected thereafter.

For the pole method, farmers use a harvesting scythe at the end of a long bamboo pole to cut the coconut bunch, which is left to drop from the palm. The advantage of this method is that it is generally faster, more efficient, less tedious and dangerous compared to the climbing method. This way, the harvester can harvest more nuts per unit time from a larger number of trees. In some coconut plantations, drains are dug out in between the rows of coconut palms, so the coconuts drop into the body of water which cushions the falling impact.

Using the climbing method (Figure 5.2), the farmer or worker is engaged to climb up the coconut tree, with or without a climbing device. For easy climbing, some coconut trees have grooves carved into their sides. Although this is dangerous, it is very commonly done to harvest coconuts. Palm climbing devices, like the ones adopted in India in Figures 5.3 and 5.4, lowers the danger imposed on the harvesters.

The advantage of climbing is that the harvester can clean and inspect the crown of the palm for pest and disease attacks. However, the grooves which are carved to construct steps in the coconut trunk make the coconut trees less suitable for timber purposes. These fractures could also be potential entry sites for pests.

Post-harvest management

Young coconuts

Bunches of young coconuts are harvested for coconut water. They are transported as whole coconuts to the processing site, where each coconut is cut from bunches in a process called de-fruiting.

Trimming

Trimming decreases the weight of the coconuts, resulting in substantial savings in transportation. It takes most of the husks away, so it is easier for consumers to drink water straight from the coconut.

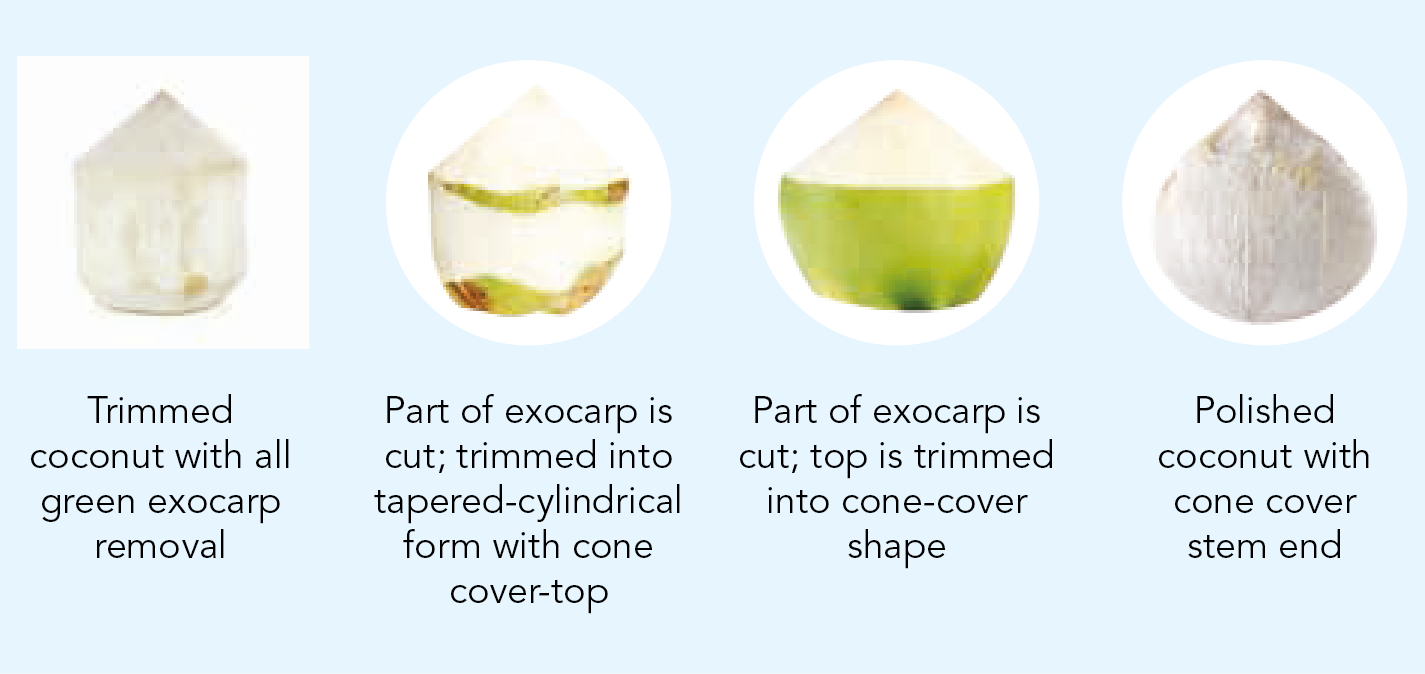

If coconuts are meant for the local market, they are distributed among the sellers in bunches or individual fruits. If the coconuts are meant for the export market, the husks are first trimmed with sharp knives. They are then trimmed again into different cut styles as seen in Figure 5.6.

Packing and pre-cooling

After trimming, the coconuts are dipped into 1-2% sodium metabisulphite solution for up to three minutes. This prevents browning and mould infection of the white husks. It can be partially substituted by using oxalic acid or a blanching process to minimize mould formation. Thereafter, young coconuts are individually packed in polypropylene or HDPE bags and then repackaged into boxes for easy transportation. These boxes are then pre-cooled to less than 4°C and stored in refrigerated conditions before transportation.

Transportation

The trimmed young coconuts are transported chilled via sea or land, and the cold chain is kept constant throughout. They are then sold in the refrigerated segments of retail channels, such as supermarkets, cafés and restaurants.

Mature coconuts

After 10-13 months, mature nuts are harvested for coconut milk and other coconut derived food products. Usually, they are gathered together on a single layer on the ground.

Some farmers practise seasoning, in which the coconuts are placed on dry ground and left to mature for another three weeks to a month, so that it is easier to dehusk, deshell and pare the testa (skin) off from the seasoned coconuts. They are also placed on dry ground as coconuts tend to germinate under damp conditions.

Dehusking

Coconuts are first dehusked before being transported by trucks, carts or boats to the processing site. Otherwise, they can be bulky. Dehusking can be done manually or by semi-automated procedures, but the former is more commonly used.

In manual dehusking, a sharp-pointed shard of steel is used. It is positioned vertically with the point up and the broader part firmly placed on the ground. The worker is trained to impale the coconut on the sharp point with a strong, determined downward movement. A few impaling strokes loosen the husk, which comes off in one or a few pieces. As this is a dangerous method of dehusking, some mechanical coconut dehuskers have been developed which are capable of dehusking 300-1200 coconuts per hour (Figure 5.7).

Deshelling and paring

Dehusked coconuts are then transported to processing sites to remove their shell and optionally, the skin. Next, they are further processed into coconut milk, cream or other coconut derived food products like desiccated coconut.

Copra

For coconuts which are specifically used for copra, they have to undergo a seasoning stage in order to increase copra recovery and quality.

Ripening for copra processing

For copra, it is recommended that the harvested nuts undergo a further ripening stage on dry ground for a month. This promotes desirable changes in the greener or somewhat less mature nuts, which is said to improve the quality of the coconut kernel, thereby reducing the tendency to produce rubbery copra, making dehusking a much easier process.

Kernel drying for copra processing

After seasoning, the coconuts are dehusked and split so the coconut water is thrown away and lost to the soil. Alternative uses for coconut water like biogas generation, or processing and packaging for ready- to-drink purposes, can also help to reduce pollution. The coconut kernel is then dried under the sun or in a kiln, hot air dryer. This improves oil yield and reduces aflatoxin incidence.

Harmful to humans and animals, aflatoxin occurs when mould, such as Aspergillus flavus, grows on improperly dried copra. Drying the kernel reduces the moisture content from 50% down to 6%, resulting in copra. It is then sent to the processing site for oil extraction.