The Chemistry of Coconut Milk and Cream

Coconut milk and cream is a white, opaque protein-oil-water emulsion used in many traditional Asian cuisines. It is a milky fluid obtained by manually or mechanically extracting fresh kernel.

The quality attributes are affected by many factors, such as the variety of nuts, water quality and volume used for coconut milk extraction. Due to its high oil content, coconut milk products are highly susceptible to chemical and biochemical spoilage, like lipid oxidation.

For coconut milk and cream products, fat content is the important criteria for categorization. According to Codex Standards for Aqueous coconut products (CODEX STAN 240-2003), coconut milk should contain at least 10% fat, 2.7% non-fat solids, and 12.7-25.3% total solids. For coconut cream, it should contain at least 20% fat, 5.4% non-fat solids and 25.4-37.3% total solids (Table 8.1).

Composition of coconut milk

The composition of coconut milk is affected by the composition of coconut kernel. It is important to highlight that the difference in oil content at various ages of the coconut kernel relates to the yield and quality of coconut milk obtained (see Chapter 3, Table 3.6).

While a young coconut at eight to nine months old has only about 18-26% oil content, a mature coconut at 10-13 months has up to 43% oil content. As a result, these mature coconuts are typically harvested for coconut milk production.

Other than the age and type of the coconut, the composition of coconut milk (Table 8.2) is also dependent on the extraction process (refer to Chapter 6).

Coconut milk is a very rich medium that supports the growth of common spoilage microorganisms, usually introduced via contaminated shells, utensils, processing equipment and handlers.

Properties and reactions of coconut milk

Like coconut water, the properties of coconut milk are affected by extraction, formulation, processing and storage. Its flavour profile is built up from acids, protein, sugars, phenolic compounds, mineral content and oil content. Its appearance is mainly affected by colour reactions and the amounts and size of the oil globules.

Chemical deterioration (mainly lipid autoxidation and lipolysis) and microbiological degradation are the two major reactions that affect the quality of coconut milk. Similar to coconut water, coconut milk is also affected by browning reactions. As a result, the white milky colour turns slightly greyish.

Chemical deterioration (lipid oxidation and lipolysis)

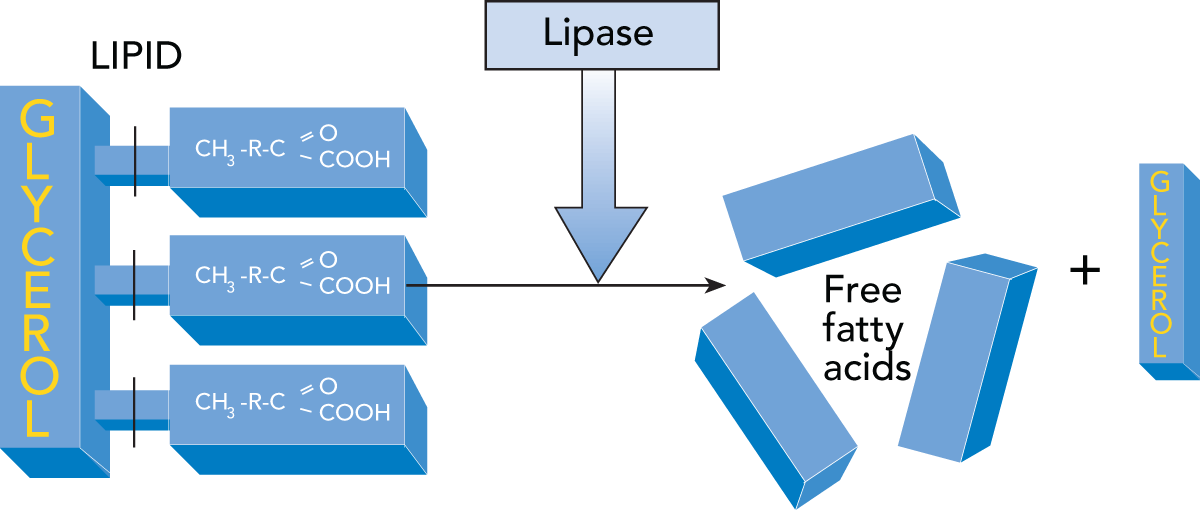

When chemical deterioration occurs, lipid oxidation and lipolysis

of unsaturated and saturated fatty acids in coconut milk results in objectionable taste and odours. The hydrolysis of triglycerides can be particularly rapid when catalysed by the lipase enzyme. The release of short-chain fatty acids, specifically butyric, caproic, caprylic, and capric acids, can give rise to strong off odours. Medium-chain fatty acids, such as lauric and myristic acids that are typical of coconut

oil also produce a distinctive soapy taste. Lastly, oxidative rancidity occurs when unsaturated fatty acids are oxidized.

The oil content of coconut milk is characteristically made up of medium chain triglycerides of saturated fat. About 5.5% of the

oil content is monounsaturated fatty acids and another 2% is polyunsaturated fatty acids. These triglycerides are susceptible to hydrolysis into free fatty acids by lipoxygenase and lipase enzymes, which are naturally present in coconut milk.

Discolouration

Similar to coconut water, discolouration reactions in coconut meat are caused by enzymatic (polyphenol oxidase, PPO and peroxidase, POD) reactions (Siriwongwilaichat et al., 2004). This results in discolouration of the coconut milk. Discolouration reactions in coconut milk are also non-enzymatic browning. The colour, turbidity, and opaque appearance of coconut milk is also affected by the size of the dispersed oil globules which have light scattering properties. In general, when oil globules are smaller, the reflectance increases, imparting a whiter colour to coconut milk.

Separation

Depending on consumer perception, the separation of coconut milk into two layers is quite subjective. When left to stand, coconut milk tends to separate into an oil-rich top and a water-rich bottom.

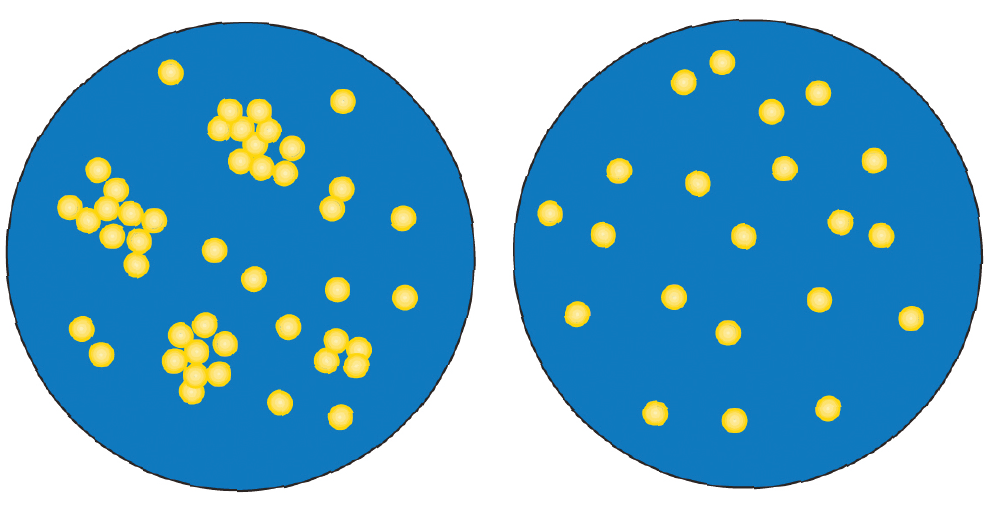

When used to cook traditional Asian cuisine, coconut milk can also contribute to the final taste and look of the dish. In most ASEAN countries, consumers perceive dishes to be of good quality when it comes with a layer of oil at the top (Figure 8.1). However, in Sri Lanka, the same dishes are perceived to be of bad quality (Figure 8.2).

Coconut milk is an oil-in-water emulsion (Figure 8.3). This means that coconut milk is insoluble or miscible in water, and has a fine dispersion of minute droplets of coconut oil in water. In addition, the emulsion may also contain emulsifiers and thickening agents that hold these two phases together. Coconut milk has naturally occurring proteins like globulins and albumins, as well as phospholipids like lecithin and cephalin to act as natural emulsifiers. To some extent, these help to stabilize the emulsion, serving as the surface between oil and water.

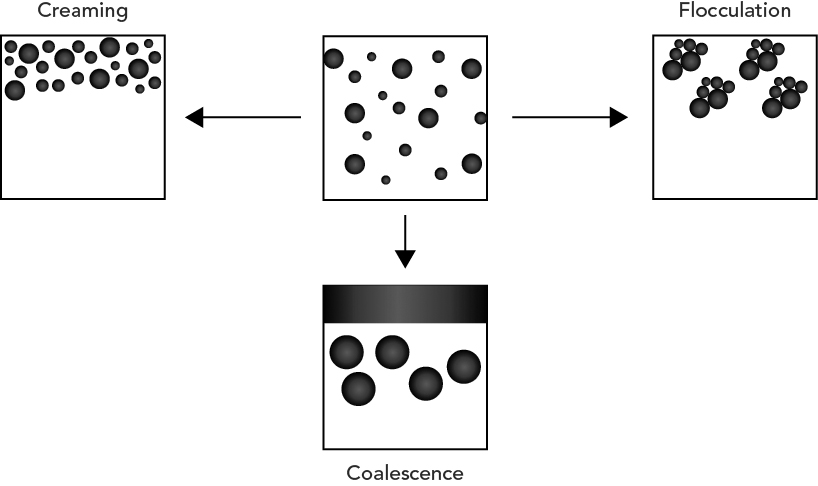

As with all emulsions, coconut milk is physically unstable and prone to phase separation as the protein content and quality in coconut milk is not enough to stabilize fat globules (Figure 8.4).

Emulsion stability is quantified by the creaming index of coconut milk samples, which results from the action of gravitational force on phases with different densities. A higher creaming index indicates the tendency to aggregate oil droplets, which destabilizes and separates the emulsion (Figure 8.4).

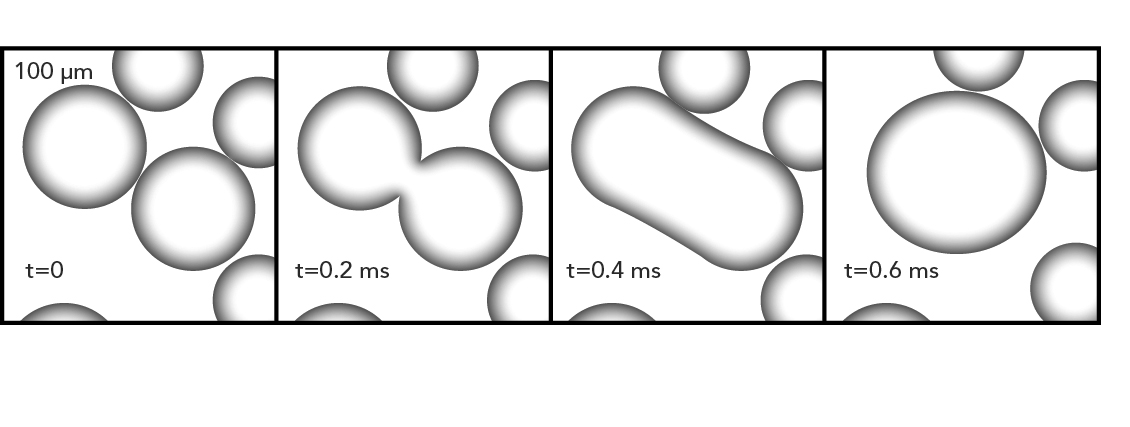

Flocculation is another destabilizing mechanism for emulsions, as fat globules move as groups rather than as individuals. This increases the chances of creaming. Contrary to flocculation, coalescence involves the rupture of interfacial film, a joining of globules, and a reduction in the interfacial area (Figure 8.5). Contact of globules must preclude coalescence, and this can occur through flocculation, creaming (Figure 8.4), or Brownian movements when particles move randomly.

Typically, the use of emulsifiers and thickening agents (stabilizers) at levels less than 2% with homogenization can improve emulsion stability of coconut milk.

Emulsifiers are amphiphilic, surface-active substances that help to retard the phase separation. This is done by absorbing to the oil- water interface, thereby lowering the interfacial tension. Proteins that naturally occur in coconut can act as emulsifiers. For commercial production, emulsifiers can be added to improve the stability for longer product shelf life.

Thickening agents or stabilizers are hydrocolloid materials that provide stabilization for emulsions, suspensions and general thickening properties. They are used widely for their unique textural, structural, and functional characteristics in food. Many do not function as true emulsifiers as they lack the necessary combination of strong hydrophilic and lipophilic properties in a single molecule. Instead, they stabilize the emulsions by thickening or increasing the viscosity of the product. This lowers the rate of separation between the oil and water layers.

Protein interactions

Small amounts of protein in coconut milk act as natural emulsifiers. As charged and surface-active molecules, they can help formulate and improve the stability of oil-in-water emulsion. Absorbing at the surface of the droplets, protein provides repulsive interactions like electrostatic and steric effects to prevent droplet aggregation. On dry basis, coconut milk consists of 5-10% protein, 80% of which are albumin and globulins. Only 30% is dissolved in aqueous phase, and the undissolved proteins act as emulsifying agents closely associated with oil globules.

pH, ionic strength and temperature affects the emulsifying properties of coconut protein. Coconut protein is ineffective at creating small droplets within the homogenizer, and preventing oil droplet aggregation during or after homogenization. As such, coconut protein can only help to stabilize the oil-in-water emulsion to a certain extent. This is why when left to stand, the physical separation of coconut milk into oil-rich and water-rich layers cannot be avoided. This is also true during processing and storage. As such, emulsifier or stabilizers, coupled with the use of homogenization, can help retard coconut milk’s instability, prolonging its shelf life.

Effects of environmental factors and additives on quality

Harvesting and pre-treatment of coconut kernel

For maximum yield of coconut milk, the nut should be 10-13 months mature, as oil content is at its highest. After the coconut is dehusked, deshelled and pared (optional), cleaning is done to minimize microbiological degradation. Coconut kernels are washed with diluted anti-microbial solutions and rinsed with potable water.

Homogenization

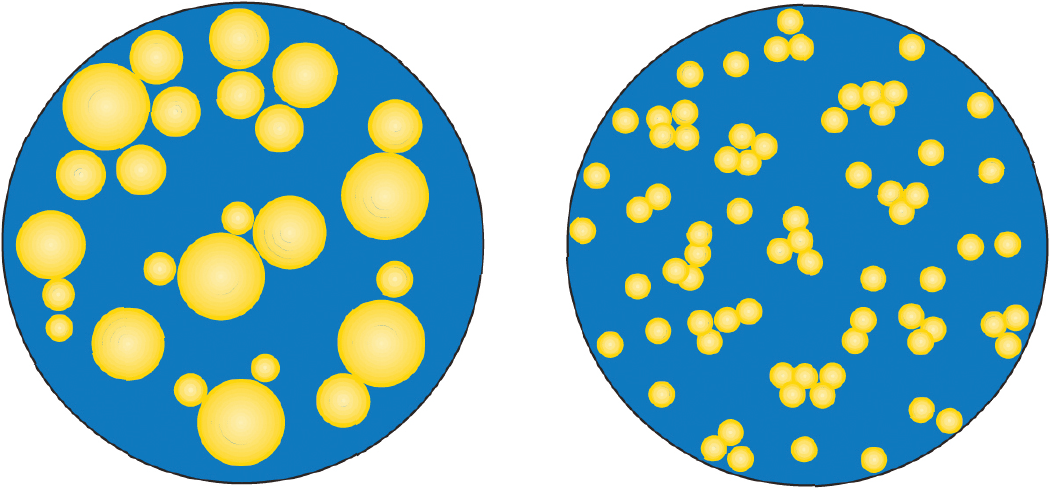

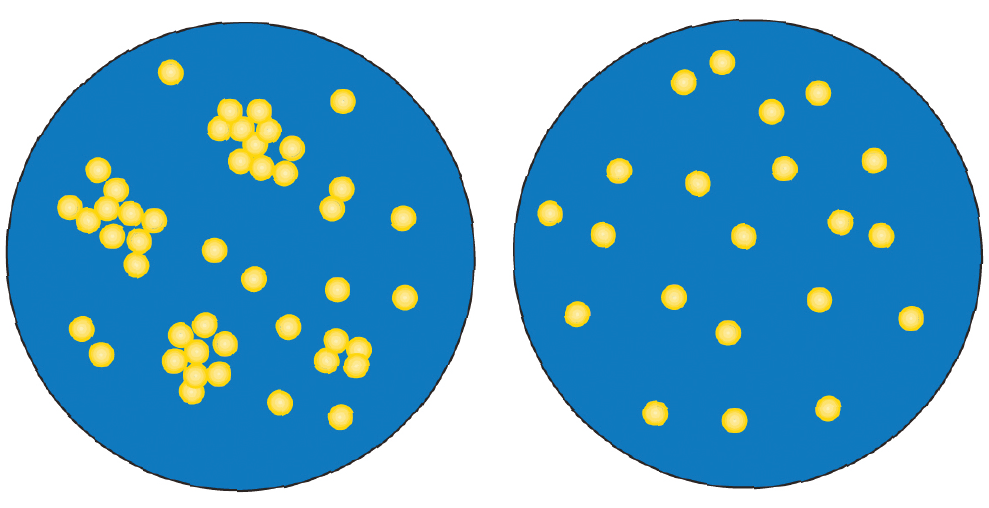

Homogenization is a means of stabilizing the coconut milk oil-in- water against gravity separation into two phases – a water-rich bottom and fat-rich top. It causes the disruption of oil globules into much smaller ones (Figure 8.6) and also separates the globules that are attached together (Figure 8.7).

Normally, this is coupled with emulsifiers that serve as surfactants that keep the globules apart. Sometimes, homogenization is also coupled with stabilizers. This increases the viscosity of coconut milk to hold the oil globules within its colloidal network.

Oxygen

Oxygen exposure can lead to the rancidity of coconut milk. This is accelerated by microbiological degradation, or the enzyme called lipase. As such, it is important to minimize oxygen exposure to prevent rancidity.

Additives

Adding stabilizers and emulsifiers

To prevent instability in coconut milk, stabilizers can be used to retard phase separation during prolonged standing. It can also thicken at the continuous phase. Alternatively, emulsifiers can be added to absorb at the oil interface.

Antioxidants

Antioxidants are added to extend the shelf life of coconut milk products. This is done by scavenging oxygen or free radicals which minimize browning reactions or lipid oxidation. In particular, sodium metabisulphite is commonly used to help retard the non-enzymatic browning of coconut milk.

Microbiology of coconut milk

Like coconut water, coconut milk is also prone to microbiological damage. Water activity, pH, temperature, oxygen availability, and light affect the growth rate of microorganisms. In particular, water activity is defined as the ratio of water vapour pressure in food to that of pure water, at the same temperature. When a solution becomes more concentrated, vapour pressure decreases. Water activity also drops from a maximum value of one for pure water.

The following systems are the major ones concerned with coconut milk and its products.

Breakdown of Carbohydrates

The breakdown of carbohydrates in coconut milk results in the production of lactic and acetic acids leading to a drop in the pH levels. This is especially so through fermentation pathways (Table 8.3). As a result, a sour taste develops in coconut milk.

Breakdown of oils

According to the Codex definition (CODEX STAN 240-2003), coconut milk and cream must contain at least 10% and 20% oil content respectively. With such a significant proportion of oil, it is very important to minimize microbial damage caused by lipolysis, also known as oil breakdown (Figure 8.8). As a result, rancidity occurs, which give rise to an off-flavour formation.

While pure oil cannot be broken down by microorganisms, oil in water emulsions or in contact with water can be easily broken down by microorganisms (Figure 8.9). This is because water is essential for microbial enzymatic split.

Breakdown of protein

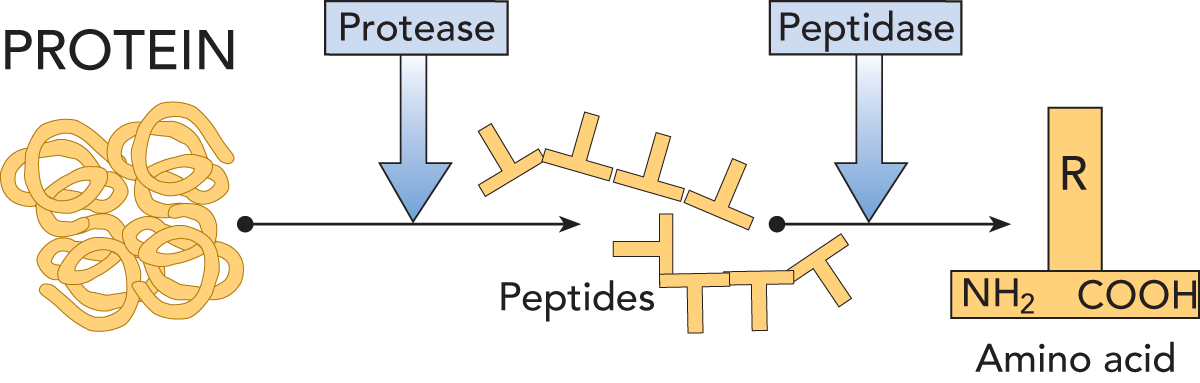

Protein denaturation is affected by the pH level of the system. The pH drop is caused by a breakdown of carbohydrates into acids. When the pH approaches the isoelectric point of the protein, it curdles as they lose their repulsive charges.

The breakdown of protein, otherwise known as proteolysis in coconut milk, can also be catalysed by proteases produced by microorganisms (Figure 8.10). Proteins and their constituent amino acids have a wide combination of chemical elements. They contain carbon, hydrogen, oxygen, sulphur, nitrogen, and phosphorus. As a result, there is a much larger range of acids, alcohols, gases (hydrogen, carbon dioxide, hydrogen sulphide and ammonia) and other compounds.